HKS 4-EL: Precisão, Flexibilidade e Desempenho Redefinidos

Versatilidade incomparável na malharia por urdidura

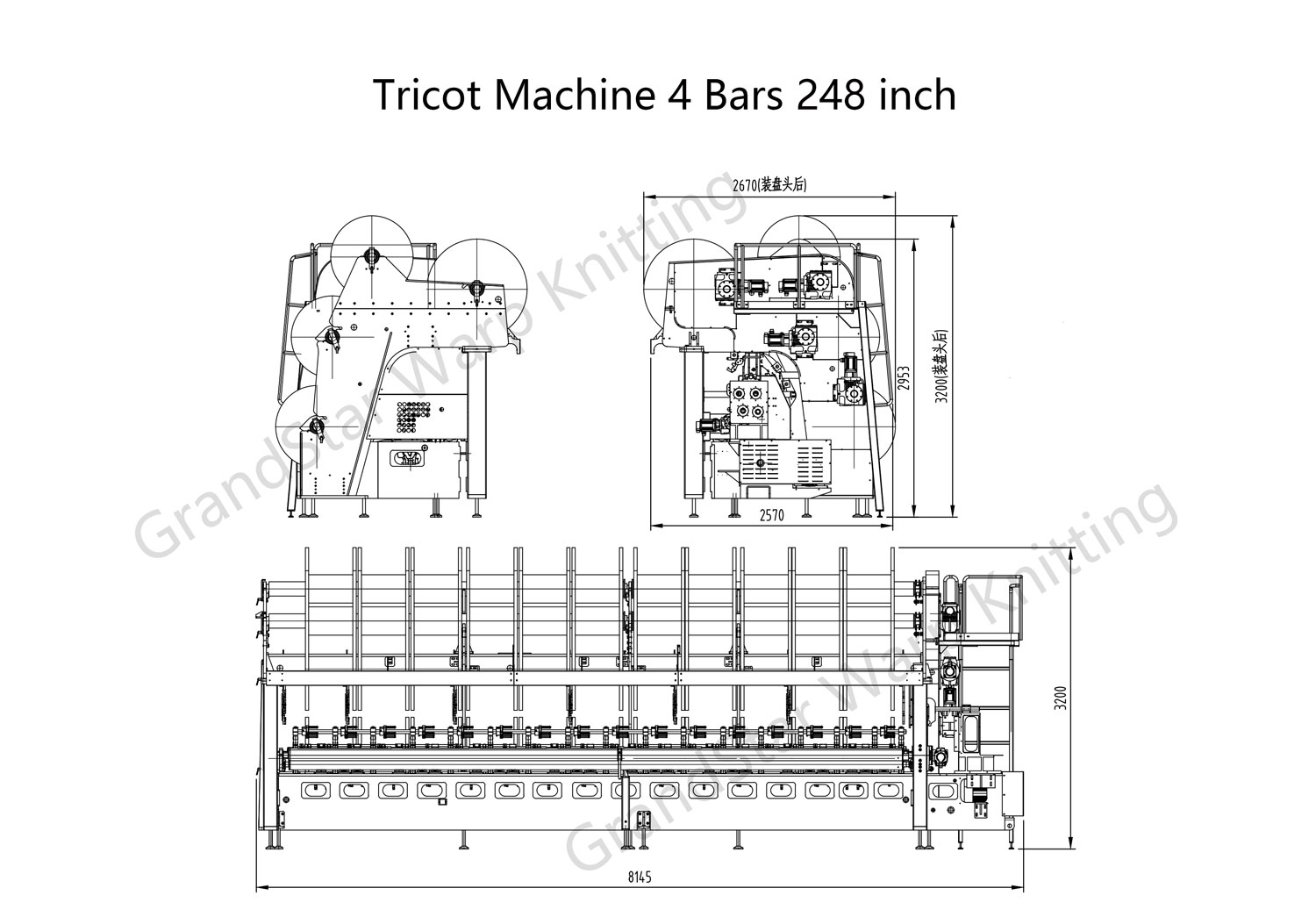

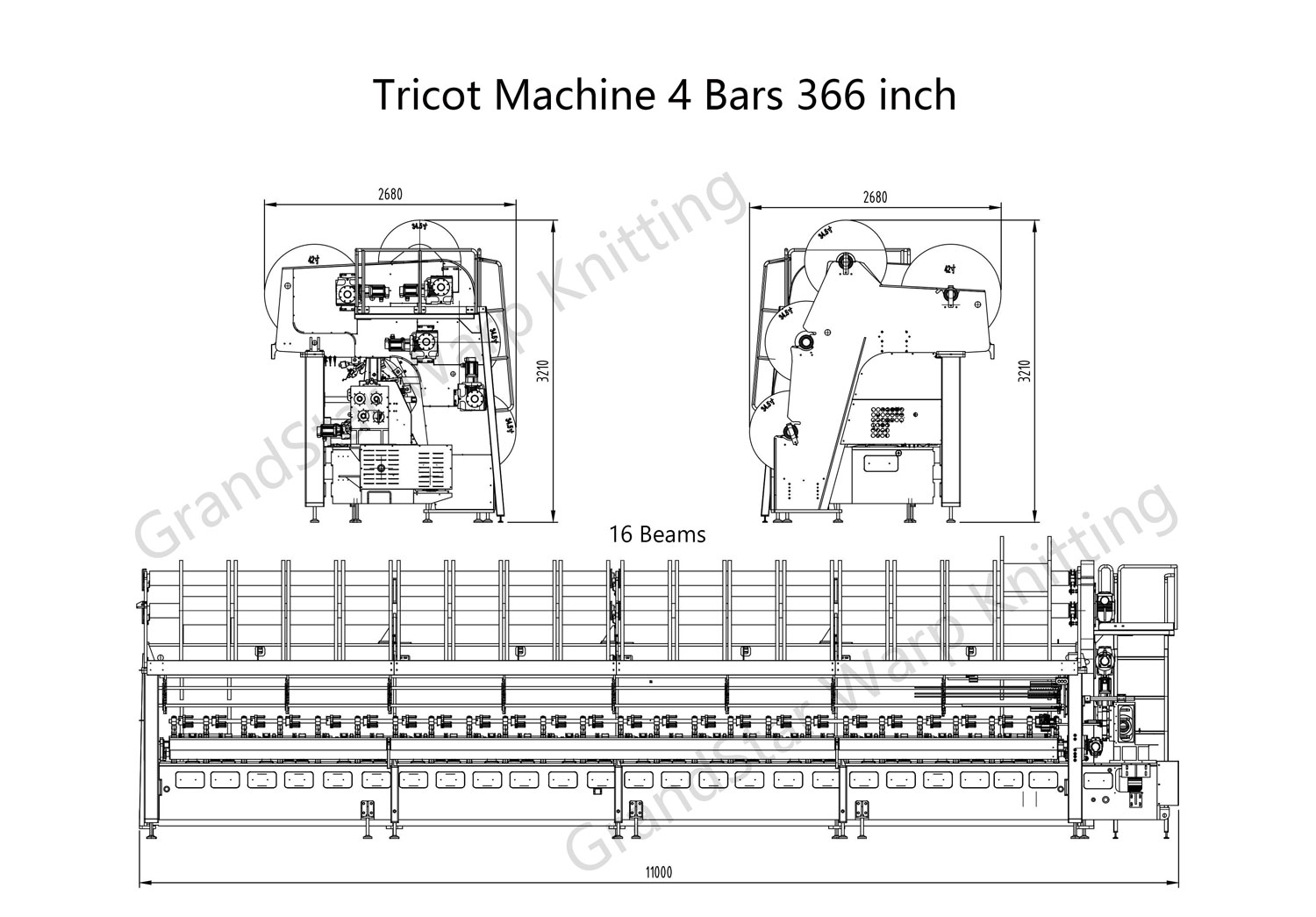

Projetado para ambostecidos de rede elásticos e não elásticos, oHKS 4-ELFoi projetado para atender às demandas em constante evolução das aplicações têxteis de alto desempenho.

EsseMáquina de tricô excepcionalmente econômicaOferece precisão, velocidade e versatilidade incomparáveis, tornando-se a escolha preferida dos fabricantes que buscam inovação e eficiência.

Principais vantagens

1. Sistema EL de ponta: Desvendando a tecnologia de padrões em zigue-zague

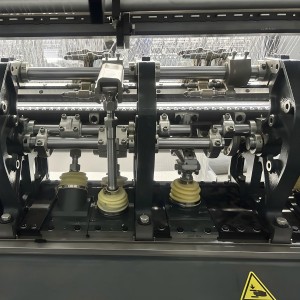

No centro doHKS 4-ELmente umsistema avançado de servoacionamento ELentregandoflexibilidade de padronização incomparável.

Essa tecnologia inovadora permite a criação perfeita depadrões intrincados em zigue-zague, ultrapassando os limites do design têxtil.

Ao contrário das máquinas convencionais que sacrificam a velocidade em prol da complexidade, asHKS 4-ELse destaca em ambas as áreas—Permitindo que os fabricantes alcancem uma produção em alta velocidade sem comprometer o controle criativo.

2. Potencial ilimitado de voltas: A vantagem do GrandStar

Tradicionalmáquina de tricô por urdiduras impõem umLimitação de 36 pontos nas opções de sobreposição, restringindo as possibilidades de design.

OO HKS 4-EL elimina essas restrições.com oSistema GrandStar, possibilitando a criação dePadrões complexos totalmente personalizadosSem qualquer limitação.

Esseinovação revolucionáriacapacita os fabricantes têxteis a explorarliberdade de design incomparável, estabelecendo novos padrões de referência no setor.

Seus benefícios

- ✔Tricô versátil de alto desempenho– atendendo a diversas aplicações têxteis.

- ✔Excelente relação custo-benefício– Maximizar o valor e a relação custo-benefício.

- ✔Velocidade de produção incomparável– alcançando uma eficiência extraordinária.

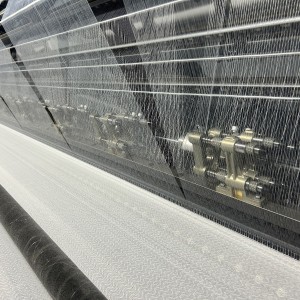

- ✔Tecnologia avançada de fibra de carbono– garantindo desempenho de ponta.

- ✔Vida útil prolongada– gerar valor de investimento a longo prazo.

- ✔Design ergonômico da máquina– Melhorando a usabilidade e a facilidade operacional.

- ✔Interface GrandStar® de última geração– para uma operação perfeita e intuitiva.

- ✔Produção de alta qualidade de forma consistente– Definindo padrões profissionais para o setor.

OHKS 4-ELé mais do que apenas uma máquina de tricô por urdidura — é umaInvestimento no futuro da inovação têxtil.

Projetado paraeficiência, durabilidade e precisãoEsta máquina permite aos fabricantes explorar possibilidades ilimitadas na produção têxtil moderna.

CONTATE-NOS

CONTATE-NOS