แผ่นลายสำหรับเครื่องถักแบบเส้นยืน

การควบคุมทางวิศวกรรมสำหรับการออกแบบผ้าที่ซับซ้อน

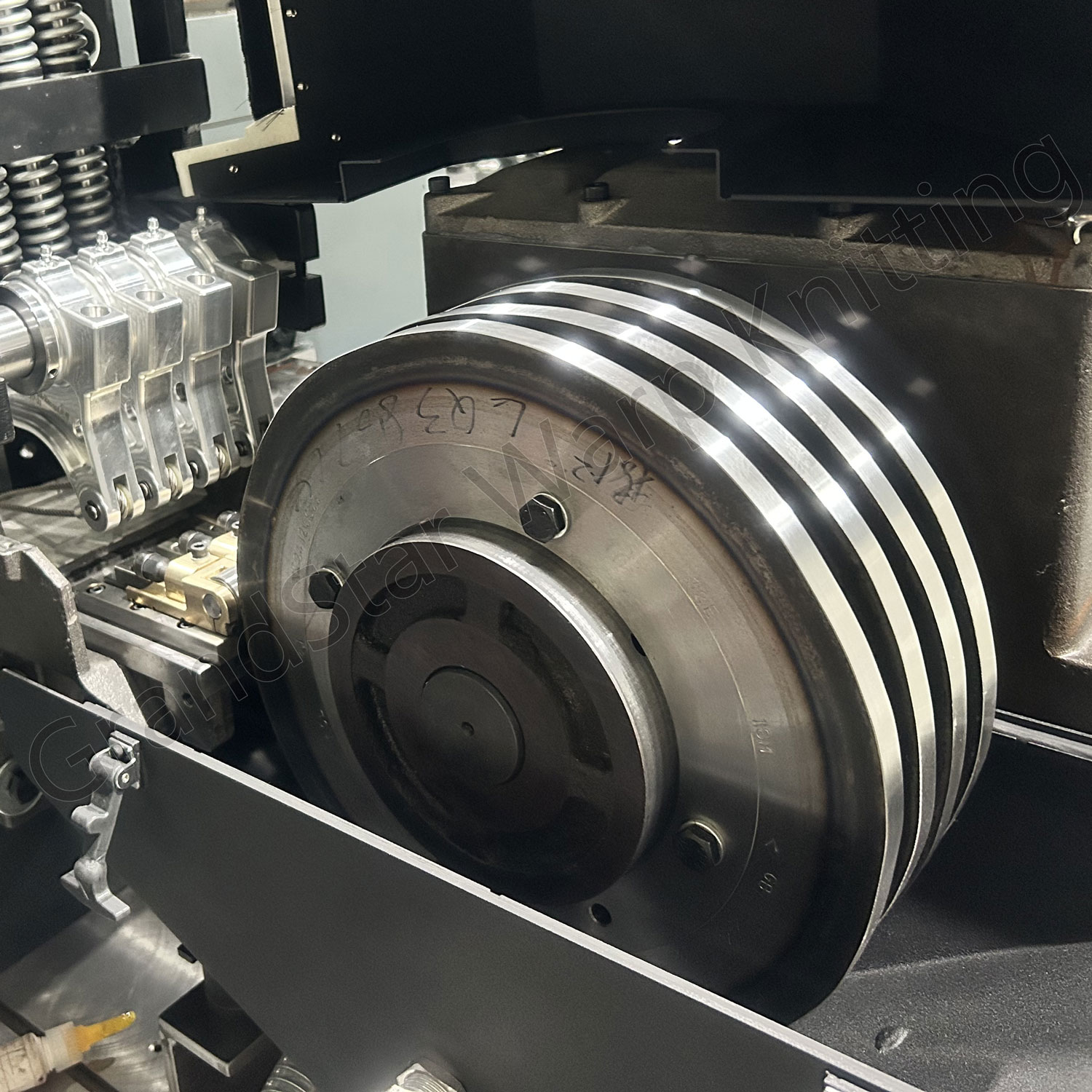

หัวใจสำคัญของการถักแบบขั้นสูงคือส่วนประกอบเล็กๆ แต่สำคัญ—แผ่นดิสก์รูปแบบกลไกวงกลมความแม่นยำสูงนี้ควบคุมการเคลื่อนไหวของแกนเข็ม โดยแปลงการหมุนเชิงกลให้เป็นลำดับการเย็บที่ควบคุมได้และทำซ้ำได้ ด้วยการกำหนดทิศทางเส้นด้ายและการสร้างห่วง แผ่นลายจึงไม่เพียงแต่กำหนดโครงสร้างเท่านั้น แต่ยังกำหนดความสวยงามของสิ่งทอขั้นสุดท้ายอีกด้วย

ออกแบบอย่างแม่นยำเพื่อความสม่ำเสมอและความซับซ้อน

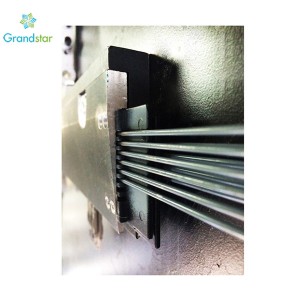

แผ่นลายของ GrandStar ผลิตจากโลหะผสมคุณภาพสูงที่ทนทาน ออกแบบมาเพื่อการทำงานความเร็วสูงอย่างต่อเนื่อง แผ่นลายแต่ละแผ่นมีช่องหรือรูที่ตัดอย่างพิถีพิถันเรียงกันรอบเส้นรอบวง ซึ่งแต่ละช่องทำหน้าที่กำหนดทิศทางการทำงานของเข็มอย่างแม่นยำ ขณะที่เครื่องจักรหมุน แผ่นลายจะประสานกับระบบเส้นยืนได้อย่างราบรื่น ช่วยให้มั่นใจได้ว่าจะจำลองแบบที่ต้องการได้อย่างสมบูรณ์แบบบนผ้าหลายเมตร ไม่ว่าจะในการผลิตผ้าไตรคอตปริมาณมากหรือการผลิตลูกไม้

รูปแบบที่หลากหลาย: จากความเรียบง่ายสู่ความซับซ้อน

ตั้งแต่รูปแบบการสอดเส้นพุ่งแบบตรงไปตรงมาและลายทางแนวตั้ง ไปจนถึงลวดลายสไตล์ Jacquard ที่ซับซ้อนและลูกไม้โปร่ง GrandStar นำเสนอแผ่นลายหลากหลายรูปแบบที่ออกแบบมาเพื่อตอบสนองความต้องการด้านการผลิตที่หลากหลาย แผ่นลายของเรามีให้เลือกทั้งแบบมาตรฐานและแบบสั่งทำพิเศษ ช่วยให้ผู้ผลิตผ้ามีความยืดหยุ่นในการออกแบบและปรับตัวได้อย่างรวดเร็ว จึงเป็นเครื่องมือที่ขาดไม่ได้ในตลาดสิ่งทอทางเทคนิค เครื่องแต่งกาย ผ้าสำหรับยานยนต์ และชุดชั้นใน

เหตุใดแผ่นดิสก์ลาย GrandStar จึงโดดเด่น

- ความแม่นยำที่ไม่มีใครเทียบได้:ผ่านกระบวนการ CNC เพื่อความแม่นยำในระดับไมครอน ช่วยให้การสร้างห่วงมีความสม่ำเสมอและการสึกหรอทางกลไกน้อยที่สุด

- ความแข็งแกร่งของวัสดุที่เหนือกว่า:ผลิตจากเหล็กอัลลอยด์ชุบแข็งเพื่ออายุการใช้งานที่ยาวนานและทนต่อความร้อนและการสั่นสะเทือน

- การปรับแต่งตามแอปพลิเคชัน:ออกแบบมาเพื่อให้ตรงกับประเภทเส้นด้ายเฉพาะรุ่นเครื่องจักร และเป้าหมายการผลิต

- การบูรณาการแบบไร้รอยต่อ:ได้รับการปรับให้เหมาะสมเพื่อให้ทำงานได้อย่างสมบูรณ์แบบกับ GrandStar และแพลตฟอร์มการถักเส้นยืนมาตรฐานอุตสาหกรรมอื่นๆ

- ช่วงการออกแบบที่ได้รับการปรับปรุง:ใช้งานได้กับระบบ Raschel และ Tricot แบบหลายบาร์และแบบกว้างเพื่อความซับซ้อนในการออกแบบสูงสุด

สร้างขึ้นเพื่อรองรับนวัตกรรมในการถักไหมพรม

ไม่ว่าคุณจะออกแบบผ้าตาข่ายสำหรับกีฬาที่ระบายอากาศได้ดี ผ้าสถาปัตยกรรม หรือผ้าลูกไม้หรูหรา แผ่นลายคือพลังเงียบเบื้องหลังลวดลาย แผ่นลายของ GrandStar ไม่ได้เป็นเพียงแค่ส่วนประกอบ แต่ยังเป็นตัวช่วยส่งเสริมความคิดสร้างสรรค์ ความสม่ำเสมอ และความแตกต่างในการแข่งขันในการผลิตผ้าประสิทธิภาพสูง

การยืนยันข้อมูลจำเพาะของแผ่นดิสก์รูปแบบ – ข้อกำหนดการสั่งซื้อล่วงหน้า

ก่อนทำการสั่งซื้อแผ่นดิสก์รูปแบบโปรดยืนยันข้อมูลจำเพาะที่สำคัญต่อไปนี้เพื่อให้แน่ใจว่ามีความเข้ากันได้กับการผลิตที่แม่นยำและการบูรณาการที่ราบรื่น:

• รุ่นเครื่องจักร

ระบุรุ่นที่แน่นอน (เช่นKS-3) เพื่อให้ตรงกับรูปทรงของดิสก์และการกำหนดค่าไดรฟ์อย่างแม่นยำ

• หมายเลขซีเรียลของเครื่อง

ระบุหมายเลขเครื่องเฉพาะ (เช่น83095) เพื่อใช้อ้างอิงในฐานข้อมูลการผลิตและการติดตามการรับรองคุณภาพของเรา

• มาตรวัดเครื่องจักร

ยืนยันขนาดเข็ม (เช่นอี32) เพื่อให้แน่ใจว่าการจัดตำแหน่งระยะพิทช์ของดิสก์ถูกต้องตามข้อกำหนดของโครงสร้างผ้า

• จำนวนแถบนำทาง

ระบุการกำหนดค่าแถบนำทาง (เช่นกิกะไบต์ 3) เพื่อปรับแต่งดิสก์ให้สร้างรูปแบบลูปได้เหมาะสมที่สุด

• อัตราส่วนการเชื่อมโยงโซ่

ระบุอัตราส่วนการเชื่อมโยงโซ่ของดิสก์ (เช่น16 ล้าน) เพื่อการซิงโครไนซ์รูปแบบและความแม่นยำของการเคลื่อนไหว

• รูปแบบโซ่เชื่อม

ส่งสัญลักษณ์โซ่ที่แม่นยำ (เช่น1-2/1-0/1-2/2-1/2-3/2-1//) เพื่อจำลองการออกแบบผ้าที่ต้องการได้อย่างแม่นยำ

ติดต่อเรา

ติดต่อเรา