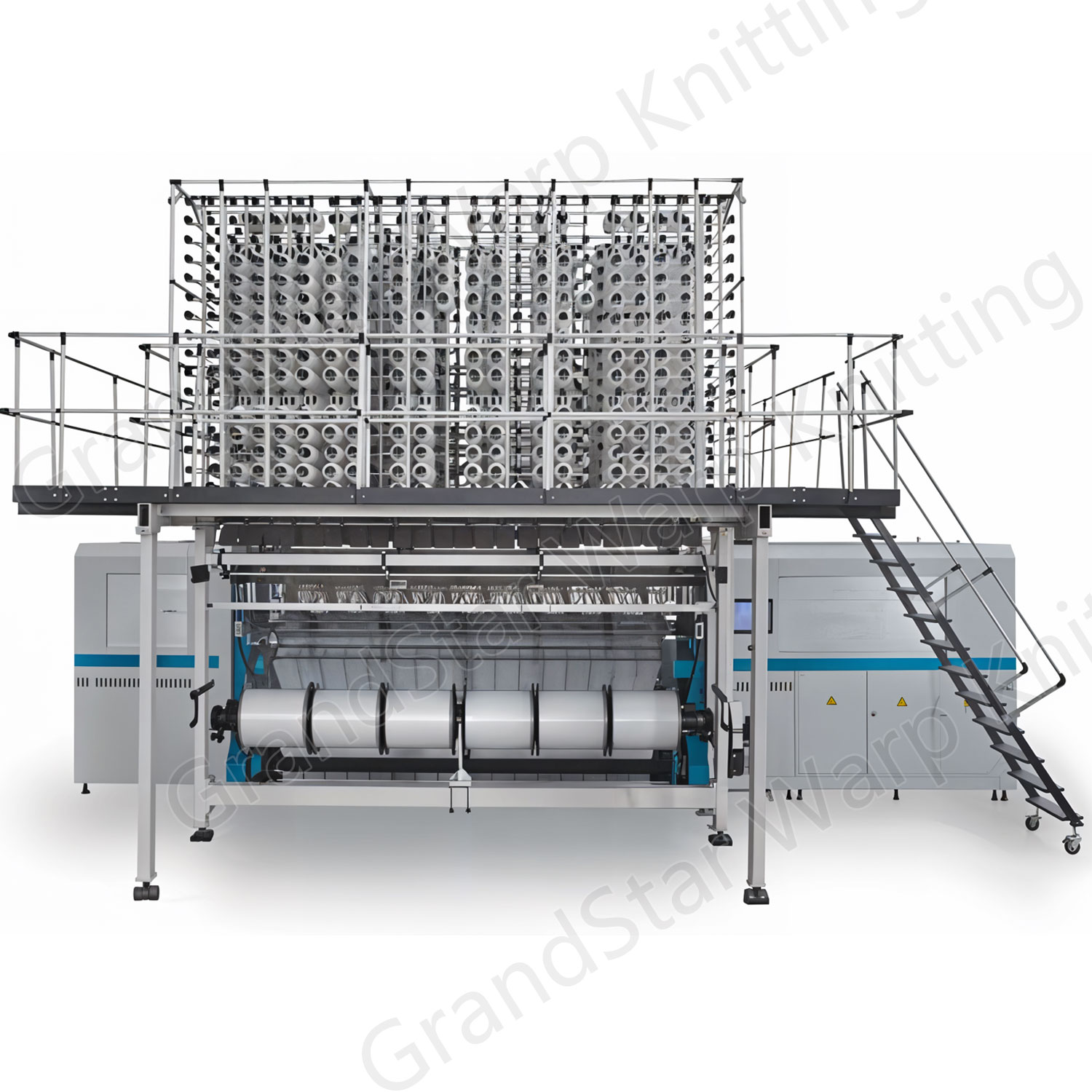

Multibar Jacquard тӯрӣ Warp бофандагӣ мошини JL75 / 1B

Jacquard тӯрӣ Multibar Raschel мошини

Дақиқии беҳамто барои истеҳсоли тӯрҳои эластикӣ ва сахт

Мошини Jacquard Lace Multibar Raschel, ки барои қонеъ кардани талаботи аз ҳама серталаби истеҳсоли тӯрӣ таҳия шудааст, як роҳи ҳалли қатъӣ барои истеҳсолкунандагонест, ки мехоҳанд маҳсулоти баландсифатро бидуни осебпазирии шакл ба даст оранд. Новобаста аз истеҳсоли тӯрҳои мураккаби чандирӣ ё сохторҳои сахт, ин мошин иҷрои устуворро бо навовариҳои тарҳрезии насли оянда муттаҳид мекунад.

Афзалиятҳои асосӣ

- Маҳсулнокии баландсуръат бо қобилияти тарроҳии мураккаб:Ҳатто барои намунаҳои хеле муфассали Жаккард маҳсулоти беҳтарини синфро пешкаш мекунад ва арзиши як метрро ба таври назаррас коҳиш медиҳад.

- Бозгашти зуди сармоягузорӣ (ROI):Барои истеҳсоли муттасил бо ҳадди ақали бекорӣ оптимизатсия карда шудааст - ба истеҳсолкунандагони матоъ барои зуд баргардонидани хароҷоти асосӣ кӯмак мекунад.

- Интегратсияи пешрафтаи Elastane:Бо ду панҷараи роҳнамои эластӣ муҷаҳҳаз шудааст, ки имкон медиҳад, ки назорати баландтари дарозӣ ва сохторҳои тӯрӣ Symm-Net барои гуногунҷабҳаи мукаммали тарроҳӣ имкон диҳад.

- То 72 сутуни намунавӣ:Маҷмӯи васеи конструксияҳои тӯрӣ ва эффектҳои мултибарро дастгирӣ мекунад, ки аз стандартҳои саноатӣ барои умқ ва дақиқии намуна болотар аст.

- Тарҳрезии ба оператор нигаронидашуда:Интерфейси барои корбар дӯстона бо мӯҳлатҳои кӯтоҳи насбкунӣ тағироти бефосилаи тарроҳиро ва зудтар ба бозор таъмин мекунад.

- Нигоҳдории паст, эътимоднокии баланд:Бо ҷузъҳои олӣ ва тарҳи механикии соддакардашуда барои кам кардани эҳтиёҷоти фарсудашавӣ ва хидмат, ҳатто дар шароити 24/7 сохта шудааст.

Чаро моро бар рақибон интихоб кунед?

Баръакси бисёре аз моделҳои рақобаткунанда, ки суръатро барои чандирии тарроҳӣ қурбонӣ мекунанд, мошини мо ҳардуро пешниҳод мекунад. Дар ҳоле, ки баъзе брендҳо шуморо ба 48 ё 60 панҷараҳои намунавӣ маҳдуд мекунанд, мо то ҳадди имкон пешниҳод мекунем72 барҳои намунавӣ— кушодани сатҳҳои нави мураккабии тарроҳӣ бидуни кам кардани суръати истеҳсолот. Ғайр аз он, технологияи хусусии мо Symm-Net бо назорати дугонаи эластӣ симметрияи истисноии намуна ва мутобиқати шиддатро таъмин мекунад - калиди бозорҳои мӯди олӣ.

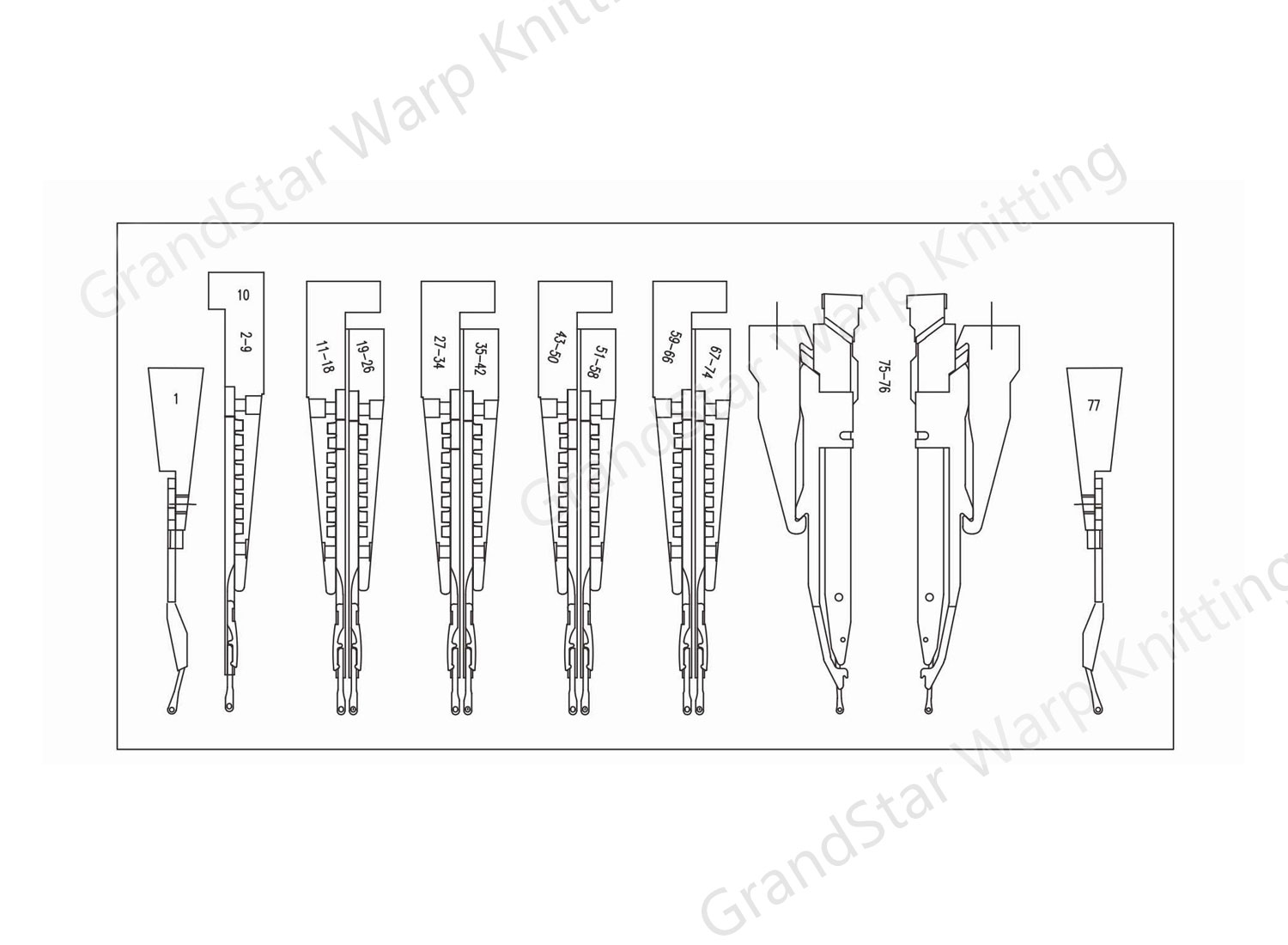

Мошинҳои мо дар муҳитҳои сермаҳсули ҷаҳонӣ дар саҳро озмуда шудаанд ва аз ҷониби истеҳсолкунандагони сатҳи баланд барои омезиши маҳорати техникӣ ва устувории корӣ эътимод доранд. Ҳар як ҷузъиёт бо дарназардошти корбари касбӣ тарҳрезӣ шудааст - аз маҷмӯаҳои бари намунавӣ то нуқтаҳои дастрасии зуди нигоҳдорӣ.

Барномаҳо

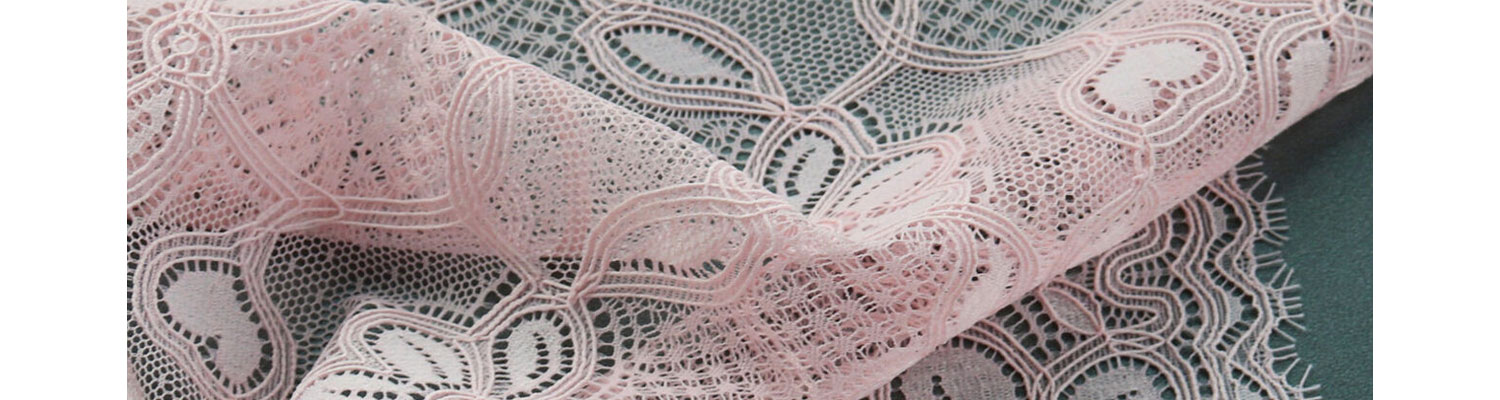

Ин мошин барои истеҳсоли тӯрӣ либоси таг, ороиши ороишӣ, тасмаҳои мӯди чандирӣ ва тӯрии пардаҳо беҳтарин аст, ки ин мошин ҳам барои истеҳсоли оммавӣ ва ҳам хатҳои махсуси маҳсулот мутобиқати олиро пешкаш мекунад.

Барои талаботи фардо тарҳрезӣ шудааст

Бо мошини Jacquard Lace Multibar Raschel, шумо на танҳо ба як таҷҳизоти таҷҳизот сармоягузорӣ мекунед, балки ба ояндаи рақобатпазир сармоягузорӣ мекунед. Суръат, дақиқӣ ва миқёспазирӣ дар як платформа муттаҳид мешаванд - омодагии истеҳсоли шуморо ба сатҳи оянда расонед.

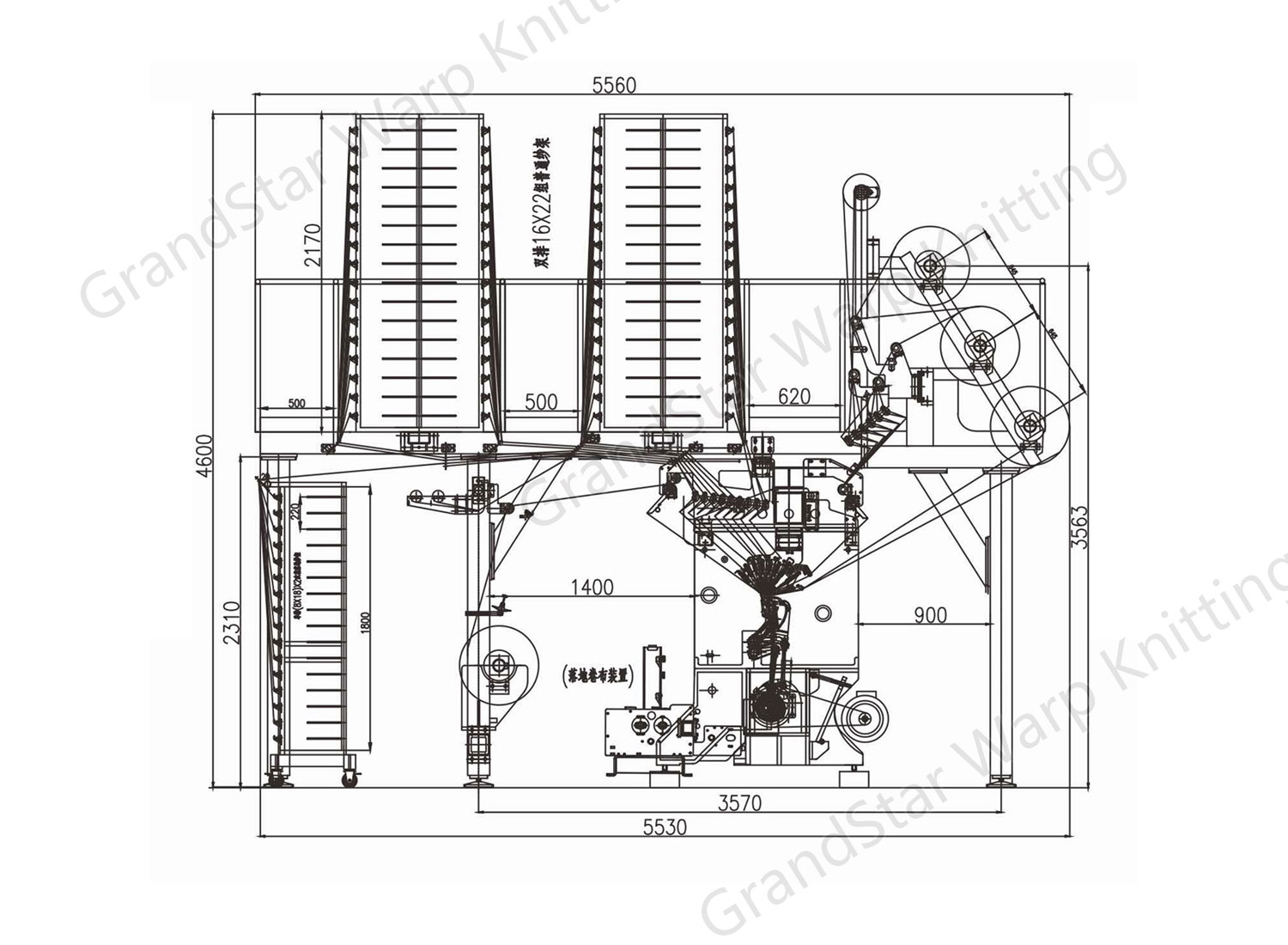

Мушаххасоти техникӣ - Силсилаи мошини бофандагии Premium Warp

Бари кор

Дар 3 конфигуратсияи оптимизатсияшуда дастрас аст:

3403 мм (134") ・ 5080 мм (200") ・ 6807 мм (268")

→ Барои ҷойгир кардани ҳам истеҳсоли матоъҳои стандартӣ ва ҳам васеъ бо дақиқии бефосила тарҳрезӣ шудааст.

Нишондиҳандаи корӣ

E18 ・ E24

→ Андозаҳои нозук ва миёна барои таърифи олии намуна дар доираи васеи барномаҳои нассоҷӣ.

Системаи резиши ришта

Фишанги сегонаи риштаи электронӣ идорашаванда барои панҷараҳои роҳнамои замин

→ Шиддати доимии риштаро бо назорати мутобиқшавӣ барои ташаккули ҳалқаи бенуқсон ва якрангии матоъ таъмин мекунад.

Намунаи Drive - EL Control

Назорати пешрафтаи бари роҳнамои электронӣ барои ҳам барҳои роҳнамо барои замин ва ҳам сатр (намуна).

→ Намунаи мураккаб ва тасҳеҳи такрории бефосила мустақиман тавассути интерфейси рақамӣ имкон медиҳад.

Консоли оператор - СИСТЕМАИ ФАРМОНҲОИ GRANDSTAR

Панели идоракунии интеллектуалии экрани сенсорӣ барои конфигуратсияи мошин, ташхис ва танзими параметрҳои зинда

→ Ба операторон имкон медиҳад, ки дастрасии интуитивӣ ба ҳар як ҷанбаи кори мошин, кам кардани вақти насб ва баланд бардоштани ҳосилнокӣ.

Шӯъбаи қабули матоъ

Системаи аз ҷиҳати электронӣ танзимшаванда бо муҳаррики фишангдор ва чор ролике, ки дар лентаи сиёҳи зидди лағжиш печонида шудаанд

→ Пешравии устувори матоъ ва шиддати пайвастаро таъмин мекунад, ки барои сифат дар истеҳсоли баландсуръат муҳим аст.

Системаи электрикӣ

Диски бо суръати танзимшаванда бо сарбории пайвастшудаи 25 кВА

→ Кори каммасрафи энергияро бо иҷрои моменти баланд кафолат медиҳад, ки барои истифодаи дарозмуддати саноатӣ беҳтарин аст.

Ин матои бефосила дар як панел истеҳсол карда мешавад, ки намунаҳои тӯрӣ ва минтақаҳои шаклсозиро бо истифода аз технологияи стрингбар муттаҳид мекунад ва multiguides бо эластанро блок мекунад. Он дорои синачаи дарунӣ бо минтақаи мустаҳкам, вале чандирӣ мебошад, ки эҳтиёҷоти зери симро аз байн мебарад ва ҳамзамон дастгирӣ ва бароҳатро беҳтар мекунад. Раванди бефосила мувофиқати ҳамворро таъмин мекунад, мураккабии истеҳсолотро коҳиш медиҳад, вақти интиқолро кӯтоҳ мекунад ва хароҷоти истеҳсолиро кам мекунад - онро барои барномаҳои самаранок ва баландсифати либоспӯшӣ дар саноати дӯзандагӣ беҳтарин мекунад.

Ин матои тӯрӣ аз техникаи намунаи буридашуда истифода мебарад, ки дар он риштаҳо берун аз майдони тарроҳӣ хориҷ карда мешаванд, то унсурҳои ҷудогона бо намуди гулдӯзӣ эҷод карда шаванд. Ин усул имкон медиҳад, ки сохторҳои хеле хуби пойгоҳ, баланд бардоштани контрасти визуалӣ байни замин ва намуна. Бо кунҷҳои абрӯвони шево дар баробари мотив ба итмом расида, натиҷа тӯри тозашудаест, ки барои мӯди олӣ, либоси таг ва либоси арӯсӣ беҳтарин аст.

Ин галлони тӯри гулҳои шево дар мошини тӯрӣ, ки бо бари пеши Жаккард муҷаҳҳаз шудааст, истеҳсол карда мешавад, ки маъмулан барои намунаҳои клип истифода мешавад. Хусусияти барҷаста дар истифодаи риштаи эластикии Бурдон ҳамчун лайнерҳост, ки ҳам матни тозашуда ва ҳам дароз карданро фароҳам меорад. Ин конфигуратсия барои либоси таги эластикии баландсифат беҳтарин аст, ки чандирии тарроҳӣ, тамомияти сохторӣ ва бароҳатии олиро таъмин мекунад.

Ин матои гуногунҷанба, ки дар як мошини тӯрӣ-маҳсули баланди Jacquard истеҳсол мешавад, чандирии истисноии тарроҳиро барои барномаҳои саноатӣ пешниҳод мекунад. Он дарозии дутарафаро барои бароҳатии беҳтар дастгирӣ мекунад, ҳамгироии логотипҳо ва шиорҳои брендро имкон медиҳад, ба истифодаи намудҳои гуногуни ришта имкон медиҳад ва метавонад эффектҳои визуалии ҳайратангези 3D -ро дар як танзимот эҷод кунад. Гарчанде ки ҳар як хусусиятро мустақилона истифода бурдан мумкин аст, онҳо инчунин метавонанд барои таъсири ҳадди аксар якҷоя карда шаванд.

Ин тӯри дарози дутарафа барқароркунии аълои чандирӣ ва дастаки ҳаҷмро дар 195 г/м² пешниҳод мекунад, ки онро ҳам функсионалӣ ва ҳам бароҳат мегардонад. Бо хосиятҳои ҳамгирошудаи танзимкунандаи иқлим, он барои либоси берунии ба ҳам наздик дар барномаҳои варзишӣ ва либоси фаъол мувофиқ буда, чандирӣ, нафаскашӣ ва эҳсоси олӣ фароҳам меорад.

Ин намунаи тӯрӣ Symm-Net тафовути ҳайратангезро байни хоки хуб, симметрӣ ва риштаи ғафс, ки тарҳи тӯрро муайян мекунад, нишон медиҳад. Бо сарҳади абрӯвони тозашуда, он дақиқ ва матнро барои истифодаи ҳамаҷониба дар либоси болопӯш, ороиши мӯд ва барномаҳои ороишӣ муттаҳид мекунад.

Муҳофизати обногузарҲар як мошин бо бастаи бехатари баҳр мӯҳр зада шудааст, ки муҳофизати мустаҳкамро аз намӣ ва зарари об дар тӯли транзит таъмин мекунад. | Қуттиҳои чӯбии содиротии стандартӣҚуттиҳои чӯбии пурқуввати мо пурра ба қоидаҳои ҷаҳонии содирот мувофиқат мекунанд, ки муҳофизати оптималӣ ва устувориро ҳангоми интиқол таъмин мекунанд. | Логистикаи самаранок ва боэътимодАз муомилоти бодиққат дар иншооти мо то боркунии коршиноси контейнер дар бандар, ҳар як қадами раванди интиқол бо дақиқ идора карда мешавад, то интиқоли бехатар ва саривақтиро кафолат диҳад. |

БО МО ТАМОС ГИРЕД

БО МО ТАМОС ГИРЕД