Mochini oa ho roka Malimo/Maliwatt

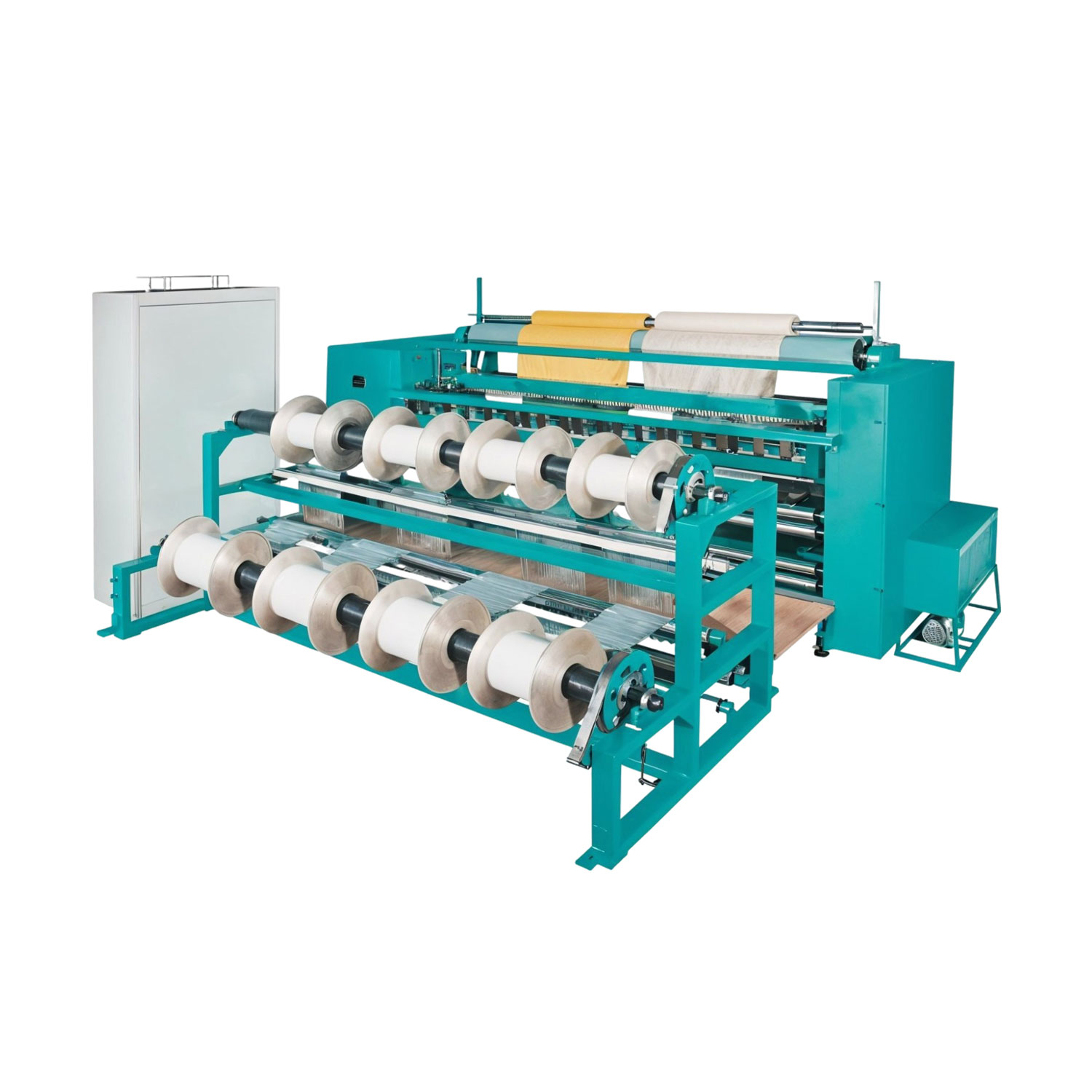

Mochini oa ho Loha oa Stitch Bonding Warp

Litharollo tse ncha bakeng sa masela a tekheniki

TheMochini oa ho Loha oa Stitch Bonding Warpke tharollo ea sejoale-joale e etselitsoeng tlhahiso eamasela a theknoloji, ka tsepamiso e khethehileng holihlahisoa tse roving le tse sa lohoeng. E sebelisoa haholo liindastering tse hlokangthepa e matlafalitsoeng e kopantsoeng, masela a tšoarellang a sa loheng, le masela a sebetsang hantle haholo.

Likopo tse fapaneng ho pholletsa le Industries

Tsa ronamochini o kopanyang li-stitche etselitsoe ho fihlela litlhoko tsa lits'ebetso tse fapaneng, ho kenyelletsa:

- Ho roala lieta- Ho matlafatsa botsitso le boiketlo.

- Mekotla ea ho reka- Ho fana ka mefuta e meng ea masela a matla le a eco-friendly.

- Masela a lijana le lithaole tse lahloang- Ho etsa bonnete ba hore ho noa haholo le ho sebetsa hantle ka litšenyehelo.

- Masela a matlafalitsoeng a kopantsoeng ka khalase ea fiber- E fana ka matla a phahameng bakeng sa lits'ebetso tsa indasteri.

Boenjiniere bo nepahetseng bakeng sa katleho e phahameng

E etselitsoetshebetso e potlakileng le e sebetsang hantle, Mechini ea rona ea li-stitch bonding e kopanyalitsamaiso tse tsoetseng pele tsa elektroniki tsa ho tlohela le li-disc tsa pateroneho netefatsaho fepa likhoele tse tsitsitseng, tse nepahetseng le boleng bo tsitsitseng ba lesela.

Likarolo tsa Bohlokoa:

- Litlhophiso tsa mochini o feto-fetohang:E fumaneha kaLitlhophiso tsa 2-bar ho isa ho 4-barho fihlela litlhoko tse fapaneng tsa tlhahiso ea masela.

- Bophara ba bophara:Ho tloha holisenthimithara tse 130 ho isa ho tse 245bakeng sa lisebelisoa tse fapaneng tsa masela.

- Sebopeho sa skrine sa touch screen se bonolo:E dumellatlhokomelo ea nako ea sebele, ho rekota data ea tlhahiso, le liphetoho tsa parameter ea lesela.

- Khokahano e bohlale:E nolofalletsaphetiso ya data e hole ka inthanete, ho ntlafatsa taolo ea tlhahiso le ho matlafatsa ts'ebetso.

Hobaneng re Khetha Mochini oa Rōna oa Stitch Bonding?

Moralo oa mochini oa rona o etelletsa pelets'ebetso e bonolo, ts'ebetso e phahameng, le ts'ebetso e phahameng ea masela. Ebang ke bakeng samasela a matlafalitsoeng a tekheniki kapa lihlahisoa tse ncha tse sa lohoeng, ronastitch bonding warp loha mochinifanabotshepehi le tlhahiso e sa bapisengho fihlela litlhoko tse ntseng li hola tsa indasteri ea masela.

Lekola bokamoso ba tlhahiso ea masela a tekheniki ka theknoloji ea rona e tsoetseng pele ea li-stitch bonding.

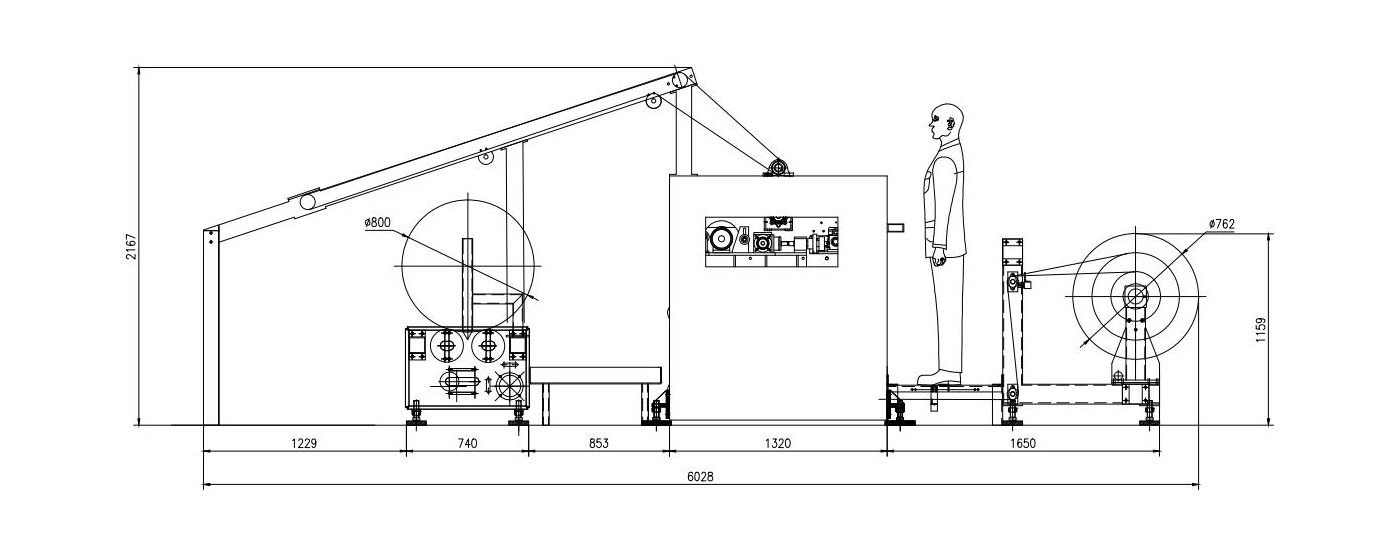

Likhetho tsa Bophara ba ho sebetsa

- 2000mm, 2800mm, 3600mm, 4400mm, 4800mm, 5400mm, 6000mm

Likhetho tsa ho lekanya

- F7, F12, F14, F16, F18, F20, F22

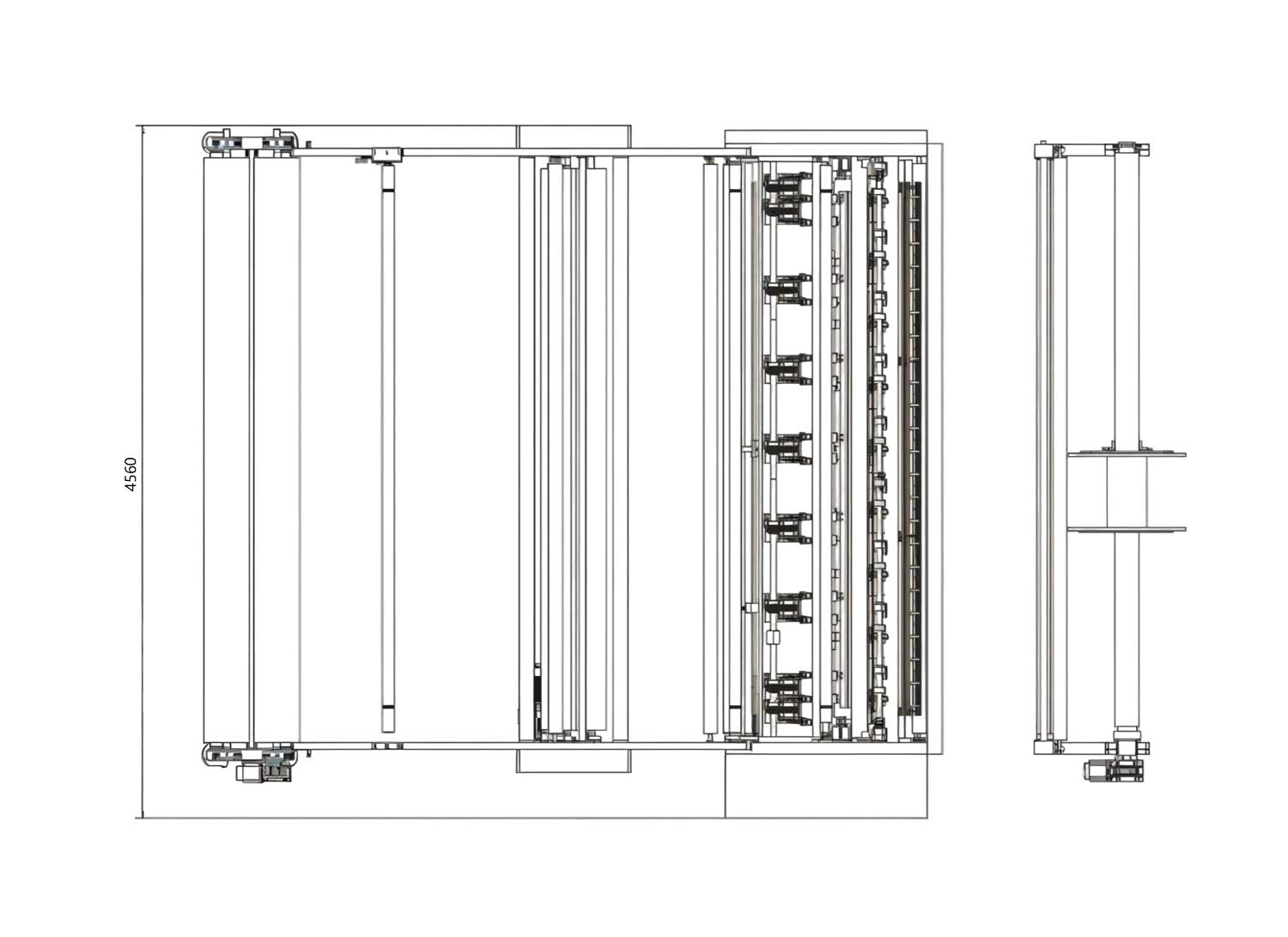

Ho loha Elements

- Motsoako oa nalebakeng sa sebopeho se nepahetseng sa loop

- Ho koala teratabakeng sa sebopeho se sireletsehileng sa stitch

- Bare ea ho kokotaho matlafatsa botsitso ba lesela

- Ts'ehetso ea barbakeng sa ho matlafatsa sebopeho

- Counter-retaining barbakeng sa ntlafatso ea ho loha ho nepahala

- Libaka tse tataisang fatše: E ka hlophisoa joalo ka1 kapa 2 mekoallobakeng sa ho feto-fetoha ha maemo

Mokhoa oa ho khanna mohlala - N

- N-drive mochineka theknoloji ea disk ea mohlala

- Tempe e kopantsoeng ea ho fetola li-gear drivebakeng sa phetoho e ntlafalitsoeng ea paterone

- Diski ea paterone e le 'ngoeho netefatsa paterone e nepahetseng le e tenyetsehang

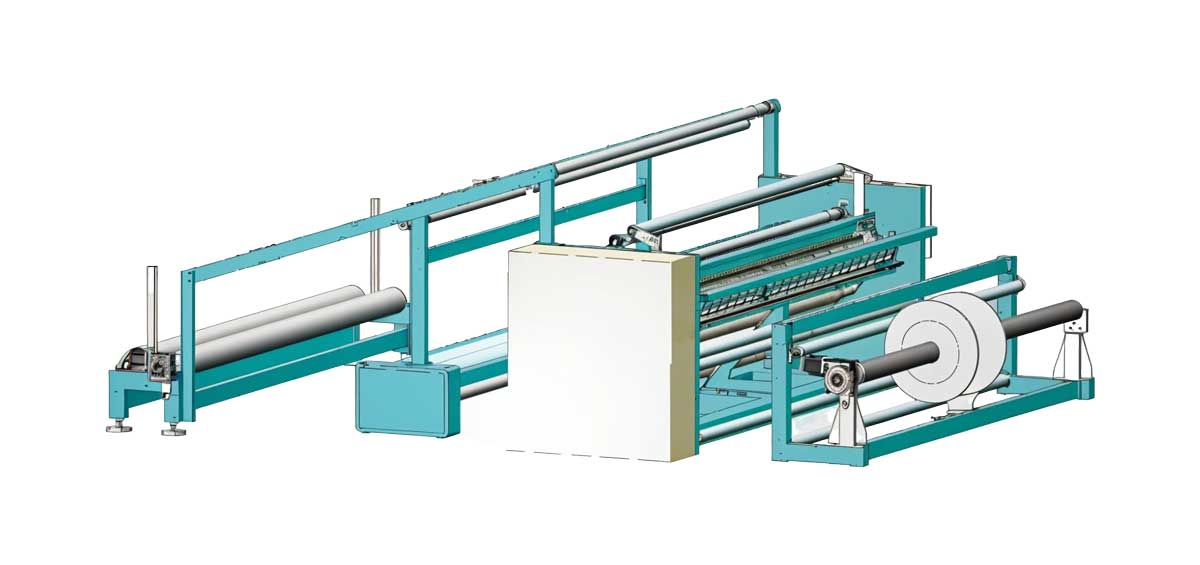

Warp Beam Support System

- E ka hlophisehang1 kapa 2 maemo a marang-rang a marang-rangbakeng sa likopo tsa likarolo

- Boholobophara ba flange: lisenthimithara tse 30, ho netefatsa katleho e ntlafetseng ea phepelo ea likhoele

Sistimi ea ho tlohela ea likhoele

- Khoele e laoloang ka mokhoa oa elektronikebakeng sa taolo e tsitsitseng ea tsitsipano

- Enjene e kentsoeng e nang le converter frequency, ho netefatsa taolo e nepahetseng le ts'ebetso e bonolo

Khoele Stop Motion (Boikhethelo)

- Sistimi e laoloang ke elektronikebakeng sa temoho e ntlafetseng ea ho robeha ha likhoele le katleho ea tlhahiso

Sistimi ea ho nka masela

- Sistimi ea ho nka lesela e laoloang ka elektronikebakeng sa ho fana ka lesela le tsitsitseng

- Enjene e kentsoeng e nang le converter frequencyho netefatsa bonnete bo phahameng le botshepehi

Sesebelisoa sa Batching (E ikemetseng)

- Friction drive e nang le roller ea khatellobakeng sa lesela le boreleli le matsoelintsoeke

- Boholobophara ba batch: 914mm (36 inch)

- Enjene e kentsoeng e nang le converter e kopaneng ea maqhububakeng sa taolo e hodimo

Sistimi e tsoetseng pele ea Taolo ea Motion

- Taolo ea Mochini: Sistimi e kopaneng ea komporo bakeng sa khokahano e nepahetseng ea koloi e kholo, ho fepa likhoele, le ho nka lesela

- Sehokelo sa Opereishene: E na le temohisisotouchscreen panelho fana ka tlhokomelo le taolo ea tlhahiso ea nako ea sebele

Sistimi ea Motlakase

- Ho khanna ka lebeloka ts'ebetso e kopaneng ea ts'ireletso ea ho felloa ke matla

- Taolo ea lebelo le le lengbakeng sa mesebetsi eohle ea mantlha ea mochini ka tsela eafrequency converter

Matla a Motlakase

- 2000mm-4400mm bophara ba ho sebetsamatla: 13 KW

- 4400mm–6000mm bophara ba ho sebetsamatla: 18KW

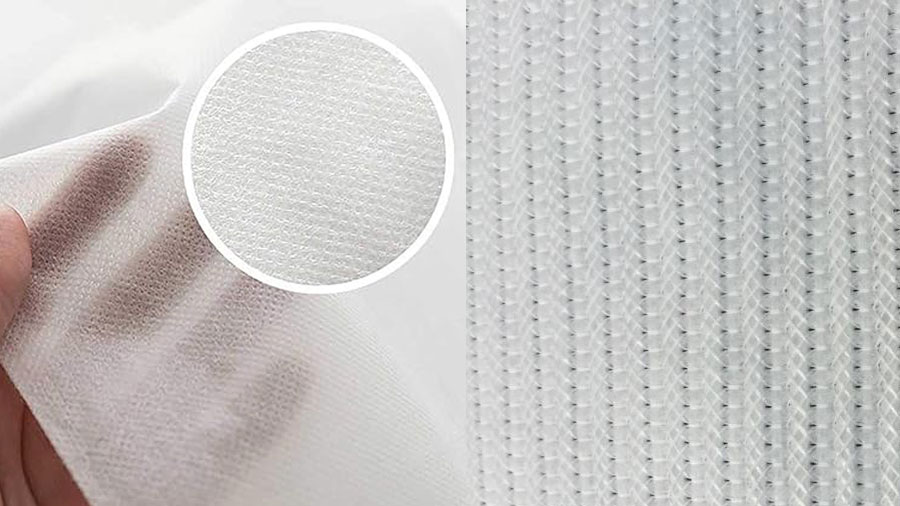

Lesela la Stitchbond le entsoe ka libotlolo tsa polasetiki tsa boleng bo holimo tse nchafalitsoeng, tse entsoeng ka fiber ea lik'hemik'hale. Ka ho sebelisa mokhoa o sa lohiloeng, o kopanya polyester e tsosolositsoeng le likhoele tsa premium polyester bakeng sa ho tšoarella le ho sebetsa.

Lesela la rona la boleng bo holimo le sa keneng metsi la spunbond le masela a hloekisang a sa lohoeng a etselitsoe ho tšoarella le ho sebetsa hantle. Ka boima ba motheo ba 33gsm ho isa ho 100gsm, masela ana a entsoe ka fiber ea tlhaho ea 100%, motsoako oa tlhaho oa fiber-polyester, kapa 100% polyester. Li fana ka matla a matla, ho hlatsuoa le ho monya metsi hantle, ho etsa hore e be tse loketseng bakeng sa ho hloekisa le lisebelisoa tsa kichineng.

Tšireletso e sa keneleng metsiMochine o mong le o mong o tiisitsoe ka hloko ka liphutheloana tse sireletsehileng tsa leoatle, o fana ka tšireletso e matla khahlanong le mongobo le tšenyo ea metsi nakong eohle ea lipalangoang. | International Export-Standard Wooden CasesLinyeoe tsa rona tsa mapolanka tse nang le matla a phahameng li lumellana ka botlalo le melao ea lefats'e ea ho romela thepa, ho netefatsa tšireletso e nepahetseng le botsitso nakong ea lipalangoang. | Lisebelisoa tse sebetsang hantle le tse ka tšeptjoangHo tloha ts'ebetsong e hlokolosi setsing sa rona ho isa ho litsebo tsa litsebi tsa ho laela boema-kepe, mohato o mong le o mong oa ts'ebetso ea ho tsamaisa thepa o laoloa ka nepo ho netefatsa hore ho tsamaisoa ho bolokehile le ka nako. |

ITEANYE LE RONA

ITEANYE LE RONA