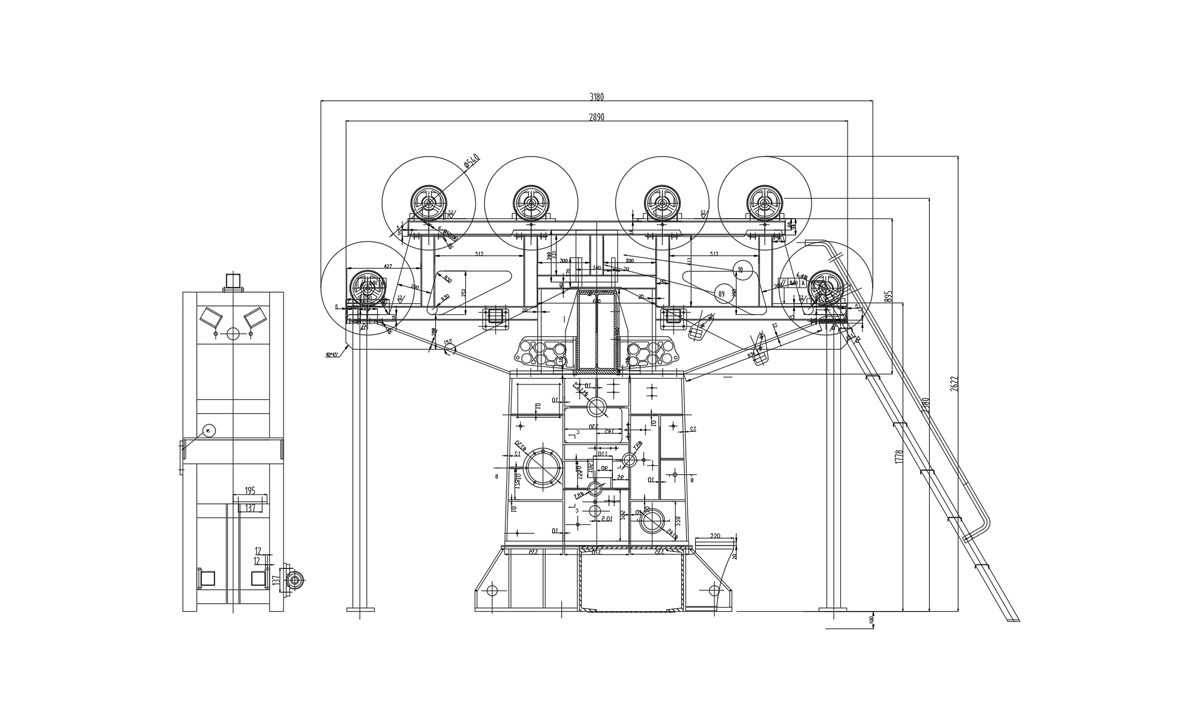

RS 2(3) Mochini oa ho Loha ka Netting Warp

Mechini e le 'Ngoe ea Raschel: Tharollo e Ntle bakeng sa Tlhahiso ea Marang-rang

Mechini e le 'ngoe ea Raschel e fana ka tharollo e ncha le e sebetsang haholo bakeng sa ho hlahisa mefuta e fapaneng ea matlooa a masela, ho kenyeletsoa temo, polokeho,

le matlooa a ho tšoasa litlhapi. Linete tsena li sebeletsa mefuta e mengata ea ts'ebeliso, 'me e' ngoe ea mesebetsi ea tsona ea mantlha ke ts'ireletso khahlanong le maemo a leholimo a mabe. Ho

maemong ana, ba tlameha ho mamella ho pepesehela khafetsa litlamorao tse fapaneng tsa boemo ba leholimo. Theknoloji e tsoetseng pele ea ho loha ea warp e kopantsoeng le Raschel e le 'ngoe

Mechini e fana ka menyetla e ke keng ea bapisoa ea tlhahiso ea marang-rang, e fetang mokhoa ofe kapa ofe oa tlhahiso ka ho feto-fetoha le ts'ebetso.

Lintlha tsa Bohlokoa tse Susumetsang Litšobotsi tsa marang-rang

- Theknoloji ea ho robala

- Palo ea mekoallo ea tataiso

- Tekanyo ea mochini

- Tlhophiso ea khoele ea khoele

- Boima ba moroko

- Mofuta oa khoele e sebelisoang

Ka ho fetola liparamente tsena, bahlahisi ba ka hlophisa thepa ea marang-rang ho fihlela litlhoko tse fapaneng tsa tšebeliso, joalo ka:

- Tšireletso ea letsatsi:Ho laola boemo ba moriti o fanoeng

- Moea o kenang ka hare:Ho lokisa khanyetso ea moea

- Opacity:Ho laola ponahalo ka letlooa

- Ho tsitsa le elasticity:Ho feto-fetoha ha maemo ka tsela e bolelele le e tšekaletseng

Mehaho ea Mantlha ea Lapping bakeng sa Tlhahiso ea Marang-rang

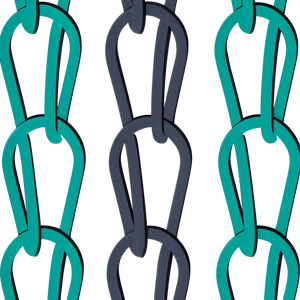

1. Moroho oa Litšiea

Themoaho oa ho roka lipilarake motheo oa tlhahiso ea marang-rang le mokhoa o sebelisoang haholo oa ho roala. E etsa bonnete ba hore

hlokahalamatla a bolelele le botsitso, e etsang hore e be ea bohlokoa bakeng sa ho tšoarella ha letlooa. Leha ho le joalo, ho theha substrate e sebetsang ea textile,

mokoloko oa litšiea o tlameha ho kopanngoa lelapping ka harekapa meaho e meng e tlatsanang.

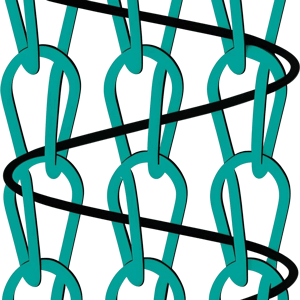

2. Inlay (Weft)

Ha asebopeho sa inlaye le 'ngoe ha e khone ho theha substrate ea masela, e bapala karolo ea bohlokoa hocrosswise botsitso. Ka

ho kopanya li-wales tse peli, tse tharo, kapa ho feta, li-inlay li matlafatsa ho hanyetsa ha lesela ho matla a lateral. Ka kakaretso, li-wales tse ngata li ile tsa ikopanya

hammoho ka underlap, le ho fetae tsitsitseng le e tsitsitsengletlooa le fetoha.

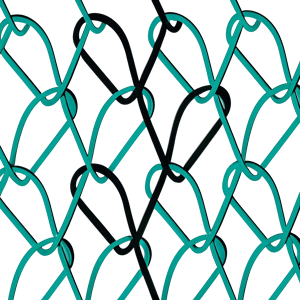

3. Tricot Lapping

Tricot lapping e fihlellwa ka hoshogging ka mahlakorengea thipa e tataisang e amanang le nale e bapileng. Ha e sebelisoa ntle le tlatsetso

tataisa mekoallo, e fella ka hahololesela la elastic. Ka lebaka la tlhaho ea eonaelasticity e phahamengka bobeli bolelele le

Litaelo tse fapaneng, ho roala ha tricot ha ho sebelisoe hangata ho etsa marang-rang-ntle le haeba ho kopantsoe le mekoallo e eketsehileng ea tataiso ho ntlafatsa botsitso.

4. 2 x 1 Lapping

E ts'oanang le tricot lapping, the2 x 1 ho qhoqhoae kopana le wales e haufi. Leha ho le joalo, ho e-na le ho theha lupu e latelang hang-hang

nale e haufi, e bōpiloe holim'a nale e latelang-empa e le 'ngoe. Molao-motheo ona o sebetsa ho li-lappings tse ngata tsa stitch, ntle le ho roka litšiea

meaho.

Ho Rala Linete tse nang le libopeho le boholo bo sa tšoaneng

Karolo ea bohlokoa ea tlhahiso ea marang-rang ke bokhoni ba ho etsa menyetla ea ho bula marang-rangboholo le dibopeho tse fapaneng, e finyelloang ka ho fetola senotlolo

lintlha tse kang:

- Mochinitekanyo

- Lapping kaho

- Boima ba moroko

Ho feta moo, thetlhophiso ea khoelee bapala karolo ea bohlokoa. Ho fapana le litlhophiso tse tloaelehileng, mokhoa oa ho roala ha se kamehla

e tlameha ho ikamahanya hantle le mochine oa ho lekanya. Ho maximize feto-fetoha, threading diphapano tse kang1 ho, 1 tsoa or

1 ho, 2 ho tsoali sebelisoa hangata. Sena se lumella bahlahisi ho hlahisa mefuta e fapaneng ea marang-rang mochine o le mong, ho fokotsa nako ea ho theoha

le ho felisa tlhoko ea ho fetoha khafetsa, e jang nako.

Qetello: Bokhoni bo Phahameng ka ho Fetisisa ka Theknoloji ea Warp Knitting

Mechini e le 'ngoe ea Raschel e fana kabokgabane bo ke keng ba lekanngoa le ho ikamahanya le maemobakeng sa tlhahiso ea letlooa la masela, ho netefatsa maemo a phahameng ka ho fetisisa ka

matla, botsitso, le ho rarahana ha moralo. Ka ho sebelisa theknoloji e tsoetseng pele ea ho loha li-warp, bahlahisi ba ka khona ho iketsetsa thepa ea marang-rang hore ba kopane

mefuta e mengata ea lits'ebetso tsa indasteri le ts'ireletso - ho beha litekanyetso tse ncha molemong oa tlhahiso ea boleng bo holimo.

Litlhaloso tsa Mochini oa ho Loha oa GrandStar® Warp

Likhetho tsa bophara ba ho sebetsa:

- 4597mm (181″)

- 5207mm (205″)

- 6807mm (268″)

- 7188mm (283 ″)

- 8509mm (335 ″)

- 10490mm (413 ″)

- 12776mm (503 ″)

Likhetho tsa ho lekanya:

- E2, E3, E4, E5, E6, E8

Lintho tsa ho Loha:

- Nale:1 ea nale e le 'ngoe e sebelisang linale tsa latch.

- Slider Bar:1 slider bar e nang le li-slider units.

- Knockover Bar:1 e kokota holim'a bara e nang le lisebelisoa tse kokotang.

- Libara tsa Tataiso:2(3) mekoallo ea tataiso e nang le likarolo tsa tataiso tse entsoeng ka nepo.

- Boitsebiso:magnalium bar bakeng sa matla a phahameng le ho sisinyeha ho fokotsehileng.

Sistimi ea ho fepa ka likhoele:

- Tšehetso ea Warp Beam:2(3) × 812mm (32″) (e sa sebetseng)

- Khoele ea ho fepa likhoele:Ho sebetsa ho tswa ho creel

- FTL:Sesebediswa sa ho seha le ho otlolla filimi

GrandStar® Control System:

TheGrandStar TAELO TS'ELISOe fana ka sebopeho sa opareitara se hlakileng, se lumellang ho hlophisoa ha mochini o sa reroang le taolo e nepahetseng ea ts'ebetso ea elektroniki.

Sistimi e Kopantsoeng ea Tlhokomelo:

- Sesebelisoa sa Lastop se Kopantsoeng:Sistimi e tsoetseng pele ea nako ea nnete ea ho lekola.

Sistimi ea ho tlosa likhoele:

Sebaka se seng le se seng sa marang-rang sa warp se na lekhoele e laoloang ka mokhoa oa elektronikibakeng sa taolo e nepahetseng ea tsitsipano.

Mokhoa oa ho nka masela:

E hlomelloa kamokhoa oa ho nka lesela o laoloang ka mokhoa oa elektronikie tsamaisoang ke enjene e sebetsang hantle haholo.

Sesebelisoa sa Batching:

A sesebedisoa sa ho roala lesela se emeng fatsheetsa bonnete ba ho boreleli lesela batching.

Mokhoa oa ho khanna mohlala:

- Tloaelo:N-drive e nang le li-disc tsa paterone tse tharo le lisebelisoa tse kopaneng tsa ho fetola tempi.

- Ka boikhethelo:EL-drive e nang le li-motor tse laoloang ka elektroniki, tse lumellang mekoallo ea tataiso ho fihla ho 50mm (katoloso ea boikhethelo ho 80mm).

Litlhaloso tsa Motlakase:

- Sistimi ea ho khanna:Koloi e laoloang ka lebelo e nang le mojaro o kopantsoeng oa 25 kVA.

- Palo ea li-volts:380V ± 10%, phepelo ea motlakase ea mekhahlelo e meraro.

- Mohala o Moholo oa Matla:Bonyane 4mm² thapo ea mekhahlelo e mene ea mantlha, terata ea fatše e seng ka tlase ho 6mm².

Sistimi ea phepelo ea oli:

E tsoetseng pelemochini o futhumatsang oli / metsie netefatsa tshebetso e nepahetseng.

Tikoloho ya Tshebetso:

- Mocheso:25°C ± 6°C

- Mongobo:65% ± 10%

- Khatello ea Phato:2000-4000 lik'hilograma / m²

Linete tsa polyethylene tse bobebe tse etselitsoeng ho boloka furu le li-bales tsa joang, hammoho le ho tsitsisa pallets bakeng sa lipalangoang. E hlahisitsoe ka mokhoa o ikhethileng oa ho roka litšiea/ho kenya, matlooa ana a na le li-wales tse arohaneng haholo le linale tse tlase bakeng sa ts'ebetso e nepahetseng. Sistimi ea batching e tiisa meqolo e hatelitsoeng ka thata e nang le bolelele bo atolositsoeng, e eketsang ts'ebetso le polokelo.

E sebelisoa haholo libakeng tse futhumetseng, matlooa a moriti a lohiloeng a sireletsa lijalo le matlo a limela ho tloha letsatsing le matla, a thibela ho felloa ke metsi 'meleng le ho netefatsa maemo a nepahetseng a khōlo. Li boetse li ntlafatsa phallo ea moea, li fokotsa ho bokellana ha mocheso bakeng sa tikoloho e tsitsitseng haholoanyane.

Tšireletso e sa keneleng metsiMochine o mong le o mong o tiisitsoe ka hloko ka liphutheloana tse sireletsehileng tsa leoatle, o fana ka tšireletso e matla khahlanong le mongobo le tšenyo ea metsi nakong eohle ea lipalangoang. | International Export-Standard Wooden CasesLinyeoe tsa rona tsa mapolanka tse nang le matla a phahameng li lumellana ka botlalo le melao ea lefats'e ea ho romela thepa, ho netefatsa tšireletso e nepahetseng le botsitso nakong ea lipalangoang. | Lisebelisoa tse sebetsang hantle le tse ka tšeptjoangHo tloha ts'ebetsong e hlokolosi setsing sa rona ho isa ho litsebo tsa litsebi tsa ho laela boema-kepe, mohato o mong le o mong oa ts'ebetso ea ho tsamaisa thepa o laoloa ka nepo ho netefatsa hore ho tsamaisoa ho bolokehile le ka nako. |

ITEANYE LE RONA

ITEANYE LE RONA