Selelekela

Ho loha ha Warp e bile lejoe la motheo la boenjineri ba masela ka lilemo tse fetang 240, e ntse e tsoela pele ka mechini e nepahetseng le boqapi bo tsoelang pele ba thepa. Ha tlhoko ea lefats'e ea masela a lohiloeng a boleng bo holimo e ntse e hola, bahlahisi ba tobana le khatello e ntseng e eketseha ea ho eketsa tlhahiso ntle le ho senya ho nepahala kapa boleng ba lesela. Bothata bo bong bo boholo bo ka hare ho pelo ea mochini o lohang oa li-warp—mochine oa kama o o haolang ka lebelo le phahameng.

Mechineng ea sejoale-joale e lohang ka lebelo le phahameng, kama e etsa metsamao e potlakileng ea lateral e hlokahalang bakeng sa ho etsa lesela. Leha ho le joalo, ha lebelo la mochine le feta ho potoloha ha 3 000 ka motsotso (rpm), ho thothomela ho fapanyetsanang, molumo oa mochine, le maemo a lerata aa eketseha. Lintlha tsena li beha boemo bo nepahetseng ba kama 'me li eketsa kotsi ea ho thulana ha linale, ho robeha ha likhoele, le ho fokotseha ha boleng ba lesela.

Ho tobana le liqholotso tsena tsa boenjiniere, lipatlisiso tsa morao-rao li tsepamisitse maikutlo tlhahlobisong ea vibrate, mohlala o matla, le mekhoa e tsoetseng pele ea ketsiso ea ho ntlafatsa motsamao oa khekhe. Sengoliloeng sena se hlahloba tsoelo-pele ea morao-rao ea theknoloji, lits'ebetso tse sebetsang, le litaelo tsa nako e tlang mabapi le taolo ea ho sisinyeha e fapaneng, e totobatsang boitlamo ba indasteri ho boenjiniere bo nepahetseng le tharollo ea ts'ebetso e phahameng.

Tsoelo-pele ea Theknoloji ho Taolo ea Vibration ea Comb

1. Mokhoa o Matla oa Moetso oa Comb System

Taba ea mantlha ea ho ntlafatsa ts'ebetso ea kama ke kutloisiso e hlakileng ea boitšoaro ba eona bo matla. Motsamao o haola oa kama, o tsamaisoang ke li-activator tse laoloang ke elektroniki, o latela mokhoa oa cyclic o kopanyang phetolelo ea lateral le oscillation. Nakong ea ts'ebetso e phahameng haholo, motsamao ona oa cyclic o tlameha ho laoloa ka hloko ho qoba ho thothomela ho feteletseng le liphoso tsa maemo.

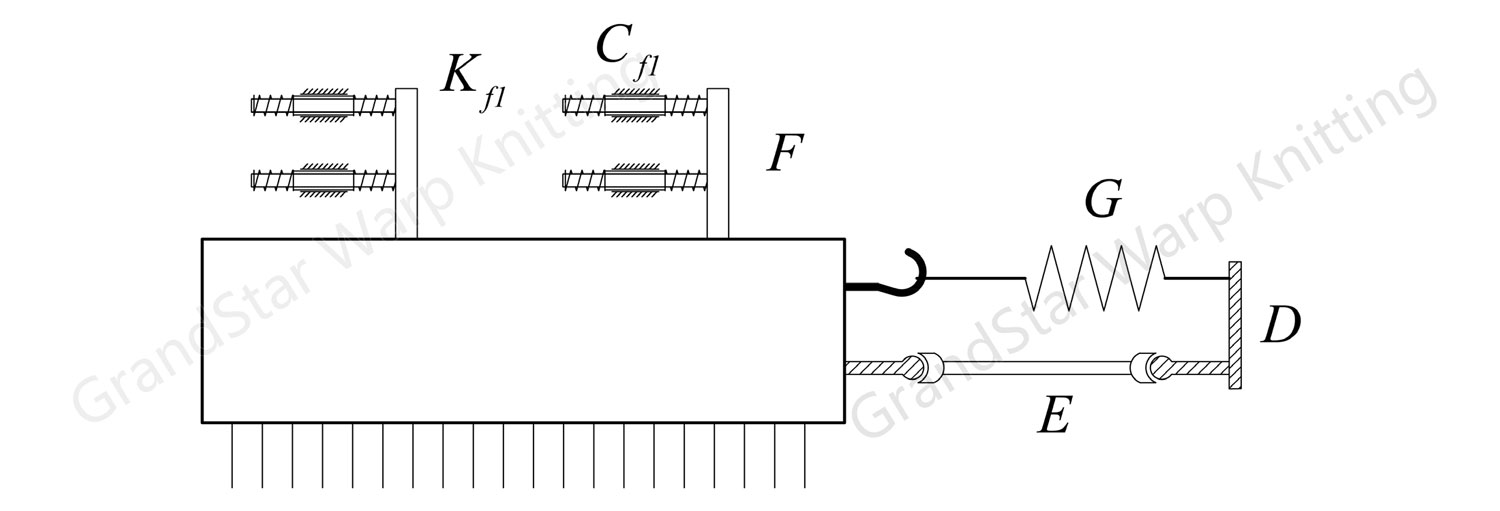

Bafuputsi ba thehile mohlala o nolofalitsoeng, oa degree e le 'ngoe oa tokoloho o shebaneng le motsamao oa lateral oa kama. Moetso ona o tšoara kopano ea li-comb, liporo tsa tataiso, le likarolo tse hokahanyang e le mokhoa oa ho futhumatsa nakong ea selemo, o arola lintlha tsa mantlha tse susumetsang ho thothomela. Ka ho sekaseka boima, ho satalla, li-coefficients tse fokolang, le matla a ho hlasimolla a kantle ho koloi ea servo, lienjiniere li ka bolela esale pele likarabo tsa nakoana le tse tsitsitseng tsa sistimi ka nepo e phahameng.

Motheo ona oa theory o thusa mokhoa o hlophisitsoeng oa taolo ea ho thothomela, ho tataisa ntlafatso ea moralo le ntlafatso ea ts'ebetso.

2. Ho Khetholla Mehloli ea Vibration le Likotsi tsa Resonance

Ho thothomela ho hoholo ho bakoa haholo-holo ke motsamao o potlakang oa kama ha ho etsoa lesela. Phetoho e 'ngoe le e' ngoe ea tataiso e hlahisa matla a nakoana, a matlafalitsoeng ke lebelo la mochini le boima ba kama. Ha lebelo la mochine le ntse le eketseha ho finyella lipakane tsa tlhahiso, ho joalo le ka makhetlo a mangata a matla ana, ho phahamisa kotsi ea ho resonance-e leng boemo boo ho bona maqhubu a excitation a ka ntle a lumellanang le maqhubu a tlhaho a tsamaiso, a lebisang ho thothomela ho sa laoleheng le ho hlōleha ha mechine.

Ka tlhahlobo ea modal ba sebelisa lisebelisoa tsa ketsiso tsa ANSYS Workbench, bafuputsi ba fumane maqhubu a bohlokoa a tlhaho ka har'a sebopeho sa kama. Mohlala, lebelo la tlhaho la tatellano ea bone le ne le baloa hoo e ka bang 24 Hz, e tsamaellanang le lebelo la mochini la 1,450 rpm. Lebelo lena la maqhubu le fana ka sebaka sa kotsi sa resonance, moo lebelo la ts'ebetso le tlamehang ho laoloa ka hloko ho qoba ho hloka botsitso.

'Mapa o nepahetseng joalo oa khafetsa o matlafatsa bahlahisi ho etsa litharollo tse fokotsang resonance le ho sireletsa bophelo bo bolelele ba mochini.

3. Mehato ea ho Fokotsa ho sisinyeha ha Boenjiniere

Litharollo tse ngata tsa boenjiniere li hlahisitsoe le ho netefatsoa ho fokotsa ho thothomela ka mokhoa o fetelletseng mochining oa kama:

- Ho Qoba Resonance:Ho fetola sebopeho sa comb, kabo ea bongata, le ho satalla ha sebopeho ho ka fetola maqhubu a tlhaho kantle ho maemo a tloaelehileng a ts'ebetso. Mokhoa ona o hloka ho leka-lekanya ho tšoarella le katleho ea tsamaiso.

- Active Vibration Isolation:Lisebelisoa tse matlafalitsoeng tsa enjene le meralo e ntlafalitsoeng ea screw ea bolo e ntlafatsa ho itšehla thajana. Ho nepahala ha phetisetso ho netefatsa motsamao o bonolo oa kama, haholo nakong ea liphetoho tse potlakileng tsa tataiso.

- Ho kopanya ha Damping:Tataiso ea liliba tse khutlang tse kenngoeng ka seporo le likarolo tsa mongobo li hatella li-micro-vibrations, ho tsitsisa lekama nakong ea mekhahlelo ea "stop-start".

- Optimized Drive Force Input Profiles:Li-profiles tse tsoetseng pele joalo ka ho potlakisa sinusoidal li fokotsa ho tsukutloa ha mochini le ho netefatsa hore li-curve tsa ho falla li boreleli, li fokotsa likotsi tsa ho thulana ha linale.

Likopo ho Indasteri

Ho kopanngoa ha mahlale ana a ho laola ho thothomela ho fana ka melemo e bonahalang ho pholletsa le ts'ebetso e phahameng ea ts'ebetso ea warp loha:

- Boleng bo Ntlafetseng ba Lesela:Taolo e nepahetseng ea kama e netefatsa sebopeho se tsitsitseng sa loop, ho fokotsa mefokolo le ho ntlafatsa botle ba sehlahisoa.

- E Eketsehile Lebelo la Mochini le Botsitso:Ho qoba resonance le karabelo e ntlafalitsoeng ea matla e nolofalletsa ts'ebetso e bolokehileng, e lebelo le holimo, e eketsa tlhahiso.

- Tlhokomelo e Fokotseng le Nako ea ho Phokotsa:Livibrate tse laoloang li eketsa nako ea bophelo ba likarolo le ho fokotsa ho hloleha ha mochini.

- Lits'ebetso tse Kholisang Matla:Motsamao o bonolo, o ntlafalitsoeng oa kama o fokotsa tahlehelo ea matla le ho ntlafatsa ts'ebetso ea sistimi.

Mekhoa ea Bokamoso le Pono ea Indasteri

Phetoho ea moralo oa mochini o lohang oa warp o tsamaellana le mekhoa ea lefats'e e totobatsang boiketsetso, digitalization le botsitso. Litaelo tse kholo tse hlahang li kenyelletsa:

- Tlhokomelo e Bohlale ea Vibration:Marang-rang a sensor ea nako ea 'nete le li-analytics tse boletsoeng esale pele li tla thusa ho lokisoa hantle le ho ntlafatsa ts'ebetso.

- Lisebelisoa tse tsoetseng pele:Li-composite tse matla haholo, tse bobebe li tla eketsa lebelo la lebelo la mochini ha li ntse li boloka botsitso.

- Digital Twin Technology:Mefuta ea Virtual e tla etsisa karabelo e matla, e lumelle ho lemoha mathata a vibrate pele ho nako nakong ea moralo.

- Moralo o tsitsitseng oa mochini:Taolo ea ho thothomela e fokotsa ho tsoa lerata le ho apara ha mechine, e tšehetsa ts'ebetso e baballang matla le e baballang tikoloho.

Qetello

Ts'ebetso ea mochini o lohang oa lebelo le phahameng e its'etleha taolong e nepahetseng ea motsamao oa kama. Patlisiso ea morao-rao e bonts'a kamoo mohlala o matla, lipapiso tse tsoetseng pele, le boqapi ba boenjiniere bo ka fokotsang ho thothomela, ho ntlafatsa tlhahiso, le ho sireletsa boleng ba sehlahisoa. Lintlafatso tsena li beha thekenoloji ea sejoale-joale ea warp ka pele ho tlhahiso e nepahetseng le tharollo e tšoarellang ea indasteri.

Joalo ka molekane oa hau eo u mo tšepang molemong oa ntlafatso ea ho loha, re ntse re ikemiselitse ho kenyelletsa tsoelo-pele ena ho litharollo tsa mochini tse tsamaisang ts'ebetso, ts'epahalo le katleho ea bareki.

Nako ea poso: Jul-07-2025

ITEANYE LE RONA

ITEANYE LE RONA