Laser Stop Bakeng sa Warp Knitting Textile Machine

Ho Khetholloa ha Lesela le Phahameng ka ho Fetisisa | Fokotsa Mefokolo ea Lesela | Fokotsa Boitšetleho ba Basebetsi

Kakaretso: Tiisetso ea Boleng ba Lesela la Boemo bo latelang

Ho loheng ha warp, esita le khoele e le 'ngoe e robehileng e ka senya botšepehi ba lesela-e leng se lebisang ho rekong chelete e ngata, litšila le kotsi ea botumo ba lebitso. Ke ka lebaka lenaSistimi ea Laser Stop ea GrandStarwas engineered/ Ketso ya ho fana: ho fananako ea sebele, mokhoa oa ho lemoha ka laser-e nepahetseng ea ho robeha ha khoele, ho fana ka litekanyetso tse phahameng ka ho fetisisa tsa taolo ea boleng tlhahisong ea masela ea morao-rao.

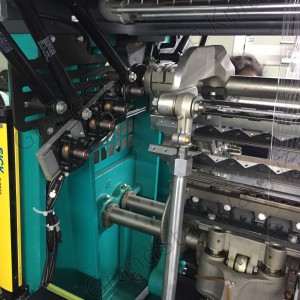

E etselitsoe ho kopana le tlhokahalo e ntseng e hola ea indasteri ea othomathike e nepahetseng, sistimi e hokahana ka mokhoa o sa reroang le mefuta e mengata e fapaneng ea lisebelisoa tsa ho loha tsa warp-haholo-holo.Mechini ea Tricot le Warping-ho emisa tlhahiso hang hang ha e lemoha ho robeha ha khoele. Sephetho:masela a se nang sekoli, litšenyehelo tse fokotsehileng tsa basebetsi, le nako e nepahetseng ea mochini.

Kamoo e Sebetsang Kateng: Tlhokomelo ea likhoele tse bohlale tse thehiloeng ho Laser

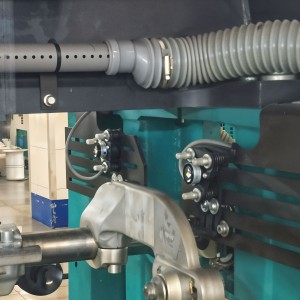

Bohareng ba tsamaiso ho na le ahigh-sensitivity laser emitter-receiver pair. E sebetsa ho melao-motheo ea lebone la laser le infrared, sistimi e lula e lekola motsamao oa khoele ho pholletsa le onaLintlha tse 1 ho isa ho tse 8 tsa mojule ka mong. Haeba khoele leha e le efe e tšela-kapa e hlōleha ho tšela-balaka ka lebaka la ho robeha, tsamaiso hang-hang e lemoha phoso ebe e romelaemisa lets'oao ho mochini oa ho loha.

Ho lemoha hona ka bohlale ho fokotsa monyetla oa ho ata ha bokooa. Sebakeng sa ho lumella mochini hore o tsoelepele ho sebetsa ka khoele e senyehileng ea warp, theLaser Stop hang-hang e emisamochini, ho sireletsa boleng ba lesela ka bobeli le bophelo bo bolelele ba mochini.

Lintlha tsa Bohlokoa le Melemo ea Setegeniki

- Multi-Head Monitoring:E ka hlophisoa ho tloha ho lihlooho tse 1 ho isa ho tse 8 mojulung ka mong bakeng sa litlhophiso tse feto-fetohang ho pholletsa le bophara ba masela le likhoele tsa khoele.

- Kutloelo-bohloko e Phahameng:Khokahano ea mahlaseli a laser le a infrared e netefatsa hore e fumaneha ka mokhoa o tšepahalang ka lebelo le phahameng le maemong a bobebe bo tlase.

- Instant Stop Karabo:Ultra-low system latency e thibela tlhahiso e sa hlokahaleng ea sekoli.

- Bophara ba Tšebelisano:E kenyellelitsoe habonolo Mechineng ea Tricot, Mechini ea Warping, le litsamaiso tsa lefa.

- E baballang Litšenyehelo le Ho Boloka Mosebetsi:E fokotsa boiteko ba ho hlahloba ka matsoho le ho tšehetsa tlhahiso e fokolang.

- Moralo oa Compact & Therability:E etselitsoe libaka tsa masela tse nang le mocheso, lerōle, le ho thothomela.

Competitive Edge: Hobaneng u Khetha GrandStar Laser Stop?

Ha ho bapisoa le li-detectors tsa khale tsa tsitsipano kapa lisebelisoa tsa ultrasonic, GrandStar's Laser Stop e fana ka:

- Ho Nepaha ha Phahameng:Theknoloji ea laser le ea infrared e feta mekhoa ea khale ea ho lemoha.

- Menyetla e fokolang ea Bohata:Sefe e tsoetseng pele e fokotsa liphoso tse bakoang ke ho sisinyeha ha tikoloho kapa liphetoho tsa mabone.

- Kopanyo e Bonolo:Moralo oa plug-and-play o netefatsa ho lumellana hamonate le likhabinete tse teng tsa motlakase.

- Botšepehi bo Pakiloeng:E lekoa ka bophara ho mekato ea tlhahiso ea lefats'e ka litlhoko tse fokolang tsa ntlafatso.

Likopo ho pholletsa le indasteri ea ho loha ea Warp

Sistimi ea Laser Stop e ts'eptjoa lits'ebetsong tse fapaneng:

- Mechini ea Tricot:Haholo-holo ea bohlokoa ka lebelo le phahameng, ts'ebetso ea lesela le letle moo khoele e robehang e bakang likoli tse bonahalang.

- Mechini ea Warping:E netefatsa boleng bo tsitsitseng nakong ea ho lokisa likhoele.

- Merero ea Retrofit:E loketse bakeng sa ho ntlafatsa lisebelisoa tsa ho loha tsa letsoho la bobeli kapa tsa lefa.

Ho tloha ho lace le liaparo tsa lipapali ho ea ho mesh ea likoloi le masela a indasteri,boleng bo qala ka ho lemoha- 'me Laser Stop e fana.

Notlolla Tlhahiso ea Zero-Defect ka GrandStar

U itokiselitse ho phahamisa litekanyetso tsa hau tsa taolo ea boleng?Sistimi ea Laser Stop ea GrandStare u fa matla a ho lekanya tlhahiso ka kholiseho ha u ntse u boloka maemo a sekoli.

P: Ho hlokahala lihlooho tse kae tsa laser bakeng sa ho lemoha ho robeha ha likhoele mochining o lohang oa warp?

A:Palo ea lihlooho tsa laser e hlokahalang e itšetlehile ka ho toba hore na ke libaka tse kae tsa likhoele tse lokelang ho behoa leihlo bakeng sa ho robeha nakong ea ts'ebetso.

Tlhokomelo ea Tsela e le 'Ngoe:

Haeba khoele e 'ngoe le e 'ngoe e feta feelantlha e le 'ngoe ea ho lemoha, joalesehlopha se le seng sa lihlooho tsa lasere lekane bakeng sa boemo boo.

Tlhokomelo ea Litsela tse ngata tsa likhoele:

Haeba khoele e tšoanang e fetamaemo a mabedi kapa ho feta a fapanengmoo ho robehileng ho hlokahalang ho fumanoa, joaleboemo bo bong le bo bong bo hloka sete ea eona ea hlooho ea laser e inehetseng.

Molao o Akaretsang:

Theho feta palo ea maemo a bohlokoa a khoele, thelisebelisoa tse ling tsa laser hlooholi hlokoa ho etsa bonnete ba hore ho behoa leihlo ka botšepehi le ka nepo.

Mokhoa ona oa modular o lumella bahlahisi ho etsa sistimi ea ho lemoha ho robeha ha likhoele ho ipapisitse le tlhophiso ea mochini, sebopeho sa masela, le maemo a boleng ba tlhahiso. Tlhokomelo e nepahetseng e thehiloeng ho laser e thusa ho fokotsa nako, ho fokotsa liphoso tsa masela, le ho boloka boleng bo tsitsitseng ba sehlahisoa-haholo-holo tlhahiso e potlakileng ea masela a tekheniki kapa a lekanyang hantle.

Keletso:Mechineng e hlahisang li-high-density kapa li-bar-multi-bar, ho eletsoa ho hlomella lintlha tse eketsehileng tsa laser ho koahela litsela tsohle tsa bohlokoa tsa likhoele, ho netefatsa litlhokomeliso tsa nako ea sebele le ts'ebetso ea ho emisa ha khoele e ka senyeha.

ITEANYE LE RONA

ITEANYE LE RONA