GS-HKS3-M: درستگي ۽ ڪارڪردگي لاءِ الٽيميٽ 3-بار هاءِ اسپيڊ ٽرائڪوٽ مشين

هڪ مشين ۾ درستگي، رفتار، ۽ ورسٽائلٽي

جيجي ايس-ايڇ ڪي ايس 3-ايمٽرائڪوٽ مشين پهچائڻ لاءِ انجنيئر ڪئي وئي آهيڪارڪردگي ۽ درستگي جو مڪمل توازن، ان کي ٻنهي جي پيداوار لاءِ مثالي انتخاب بڻائينديلچڪدار ۽ غير لچڪدار وارپ سان ٺهيل ڪپڙا. لاءِ ٺهيلورسٽائل ايپليڪيشنون، هي ماڊل هڪ غير معمولي آهياقتصاديحل جيڪو جديد ڪپڙي جي پيداوار ۾ پيداوار کي ٻيهر بيان ڪري ٿو.

اعليٰ ڪپڙي جي معيار لاءِ جديد بناوت ٽيڪنالاجي

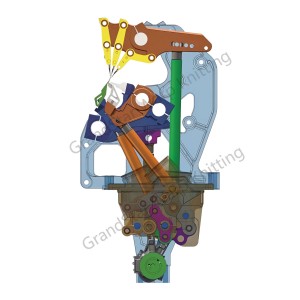

- سنڪر سوئيون ڪپڙي کي ڪنٽرول ڪن ٿيون:اهي خاص سنڪر سوئيون فعال طور تيڪپڙي جي پوزيشن کي منظم ڪريوسڄي بُنائي جي چڪر دوران، هڪ هموار ۽ ڪنٽرول ٿيل عمل کي يقيني بڻائيندي.

- جديد لوپ فارميشن:جيسنڪر سوئي جا گلاڪپڙي کي جاءِ تي رکو جڏهن تهزبان جون سُوئيون اڀرن ٿيوننوان لوپ ٺاهڻ لاءِ، گهٽ ۾ گهٽ خرابين سان اعليٰ معيار جي پيداوار جي ضمانت.

ميش کثافت ۽ نمونن ۾ بي مثال لچڪدار

- وڌايل سنڪر موومينٽ:ڪپڙي جي جوڙجڪ جي وسيع رينج کي فعال بڻائي ٿو، ڊيزائن جي امڪانن کي وڌائي ٿو.

- تيز رفتار ڪارڪردگي:حاصل ڪري ٿوغير معمولي پيداوار جي ڪارڪردگي، وڏي پيماني تي ٽيڪسٽائل آپريشن جي گهرجن کي پورو ڪندي.

GS-HKS3-M ڇو چونڊيو؟

✅ بي مثال قدر

هڪ اعليٰقيمت-ڪارڪردگي تناسبقيمت-مؤثر آپريشن پهچائڻ.

✅ قابل ذڪر رفتار

تيز رفتار بنائڻ يقيني بڻائي ٿيغير معمولي پيداوار جي ڪارڪردگي.

✅ جديد ڪاربن فائبر ٽيڪنالاجي

وڌائي ٿومشين جي استحڪام۽وائبريشن گھٽائي ٿو، اعليٰ پيداوار جي معيار ڏانهن وٺي ٿو.

✅ وڌايل سروس لائف

لاءِ ٺهيلڊگهي مدت جي اعتبار، هڪ پائيدار سيڙپڪاري کي يقيني بڻائڻ.

✅ جديد ايرگونومڪ ڊيزائن

لاءِ ٺهيلبهترين سنڀال، آپريٽر جي ٿڪاوٽ کي گهٽائڻ ۽ ڪم جي وهڪري کي بهتر بڻائڻ.

✅ نئون گرينڊ اسٽار® انٽرفيس

ايندڙ نسلبي عيب ڪنٽرول سسٽممشين جي بي عيب آپريشن لاءِ.

وارپ نِٽنگ حل

جيGS-HKS3-M 3-بار تيز رفتار ٽرائڪوٽ مشينصرف هڪ بنائڻ واري مشين کان وڌيڪ آهي - اهو هڪ جدت آهي جيڪا ڪپڙي جي پيداوار جي حدن کي وڌائي ٿي. ان سان گڏتيز رفتار صلاحيتون، جديد ٽيڪنالاجي، ۽ لچڪدار نموني سازي، اهو ٺاهيندڙن لاءِ آخري حل آهي جيڪي ڳولي رهيا آهندرستگي، ڪارڪردگي، ۽ ورسٽائلٽيوارپ بُنائي ۾.

اسان سان رابطو ڪريو

اسان سان رابطو ڪريو