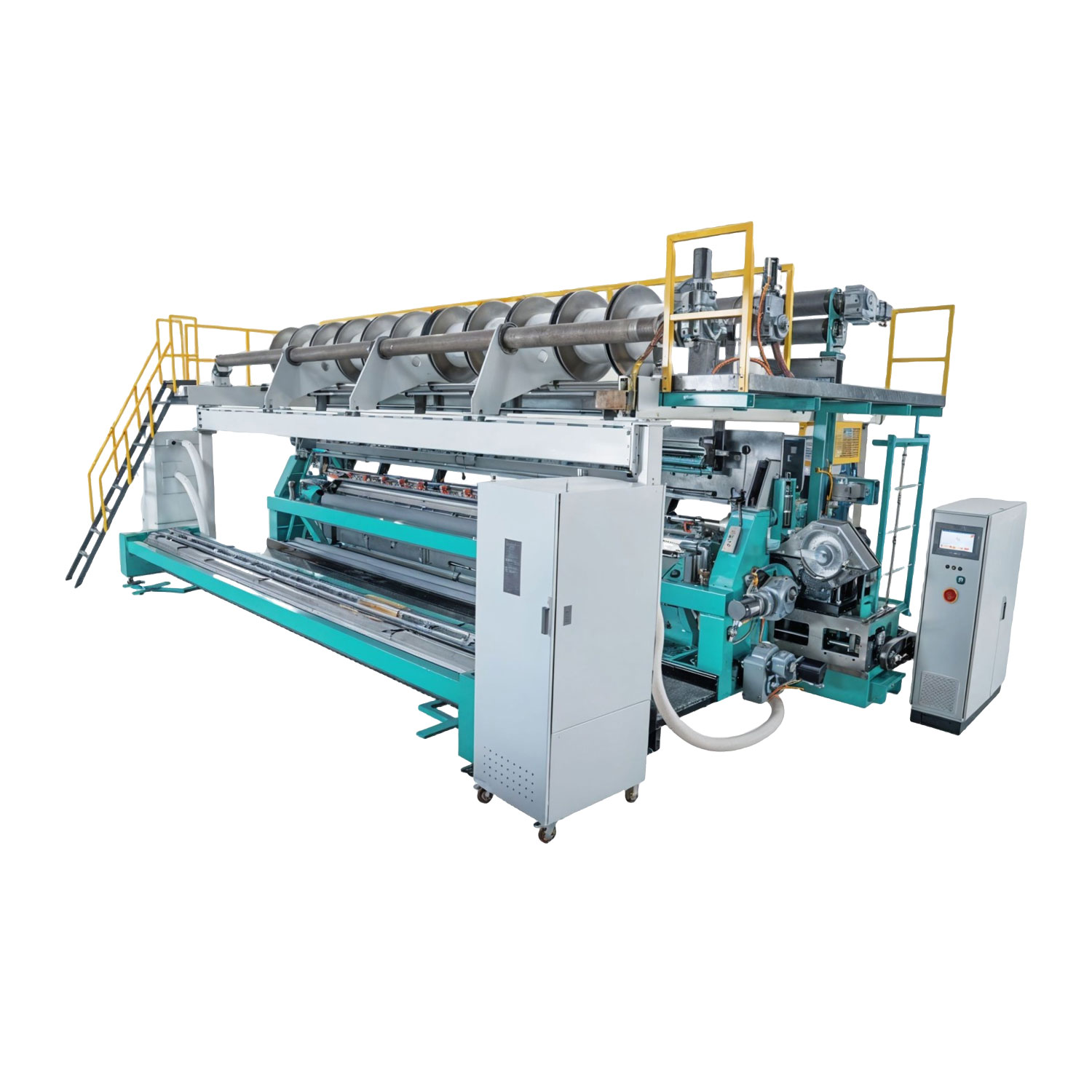

HKS2-MSUS 2 Bar Tricot Dengan Sisipan Weft

Mesin Sisipan Pakan HKS untuk Fabrik Ringan

Melancarkan Inovasi dalam Mengait Meledingkan

TheMesin pemasukan pakan HKSialah penyelesaian mengait meledingkan berprestasi tinggi termaju yang direka untuk memenuhi permintaan ketat pengeluaran tekstil moden. Kejuruteraan dengan asistem sisipan weft berorientasikan kursus, ia memberikan kecekapan dan ketepatan yang tiada tandingan dalam pembuatan fabrik ringan untuk pelbagai aplikasi.

Aplikasi Serbaguna Merentas Industri

kamiMesin pemasukan pakan HKSdireka secara pakar untuk memenuhi pelbagai keperluan industri, menawarkan fleksibiliti yang luar biasa dalam pengeluaran fabrik. Sama ada meningkatkan tekstil berfungsi atau elemen hiasan, mesin ini disepadukan dengan lancar ke dalam pelbagai aplikasi:

- Tapak Sulaman & Tulle– Menghasilkan struktur fabrik yang halus dan rumit sesuai untuk aplikasi sulaman dan renda.

- Interlinings– Menghasilkan bahan interlining yang stabil dan tahan lama yang penting untuk tetulang pakaian.

- Tekstil Perubatan– Membolehkan pengeluaran fabrik berkualiti tinggi untukpenapis hemodialisis dan pengoksigen, memenuhi piawaian penjagaan kesihatan yang ketat.

- Kain Pakaian Luar– Menyediakan tekstil ringan namun teguh sesuai untuk pakaian fesyen dan prestasi.

- Substrat Salutan & Media Pengiklanan– Menyokong penciptaan substrat tahan lama dan boleh dicetak untuk kegunaan industri dan komersial.

Faedah Luar Biasa untuk Kecekapan Maksimum

TheMesin pemasukan pakan HKSdireka bentuk untuk menyampaikan prestasi unggul, memastikan output maksimum dengan masa henti yang minimum. Faedah utama termasuk:

- Produktiviti Tinggi– Dinamik mesin yang dioptimumkan membolehkan kelajuan pengeluaran yang lebih pantas, memaksimumkan output tanpa menjejaskan kualiti.

- Pelbagai Aplikasi yang Luas– Mampu memproses pelbagai komposisi gentian dan pembinaan tekstil, memastikan fleksibiliti dalam pengeluaran.

- Teknologi Carbon Bar– Tersedia dengan bar karbon untuk kestabilan yang dipertingkatkan, memastikan pemprosesan yang konsisten walaupun di bawah suhu yang berubah-ubah.

Tingkatkan Keupayaan Pengeluaran Anda

Dengan kejuruteraan terkini dan inovasi terkemuka industri, theMesin pemasukan pakan HKSadalah pilihan ideal untuk pengeluar yang bertujuan menghasilkan fabrik ringan berkualiti tinggi dengan kecekapan dan ketepatan.

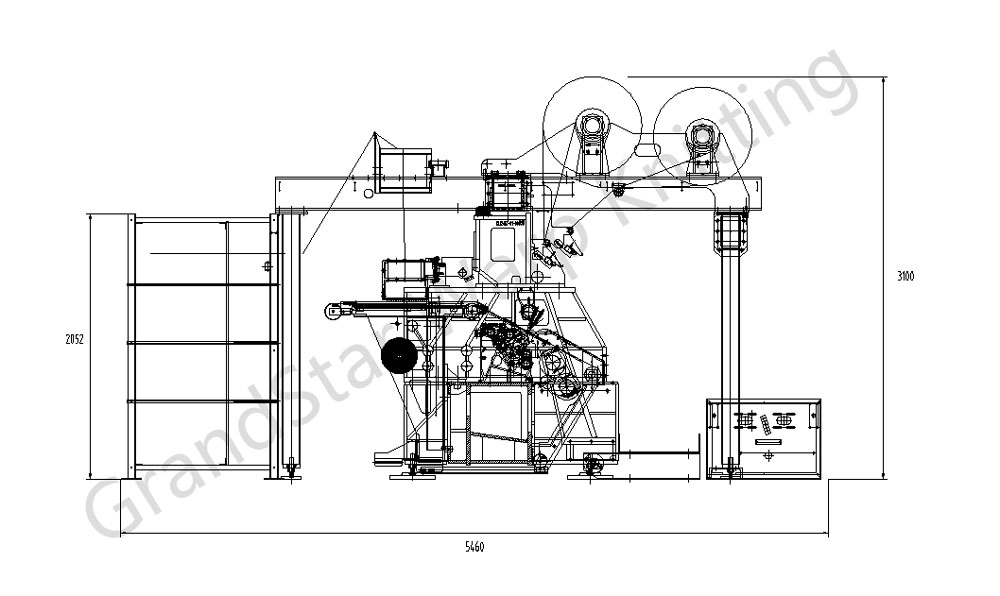

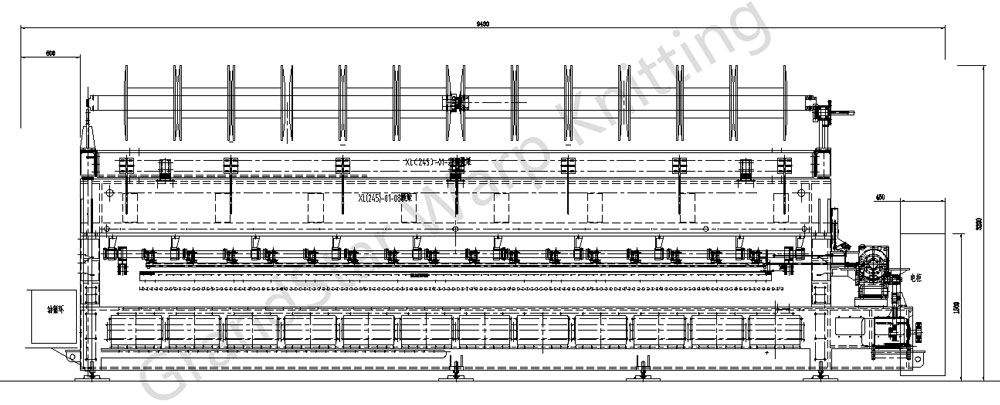

Spesifikasi Mesin Mengait Ledingkan GrandStar®

Pilihan Lebar Kerja:

- 3454mm (136″)

- 6223mm (245″)

Pilihan Tolok:

- E24 E28

Elemen mengait:

- Bar Jarum:1 batang jarum individu menggunakan jarum kompaun.

- Bar Slider:1 bar gelangsar dengan unit gelangsar plat (1/2″).

- Bar Sinker:1 bar sinker menampilkan unit sinker kompaun.

- Bar Panduan:2 bar panduan dengan unit panduan kejuruteraan ketepatan.

- Bahan:Bar komposit bertetulang gentian karbon untuk kekuatan unggul dan mengurangkan getaran.

Konfigurasi Sokongan Warp Beam:

- Standard:2 × 812mm (32″)

- Pilihan:

- 2 × 1016mm (40″) (berdiri bebas)

Sistem sisipan pakan:

- Standard:Pengangkutan meletakkan benang dengan 24 hujung

Sistem Kawalan GrandStar®:

TheSISTEM PERINTAH GrandStarmenyediakan antara muka pengendali yang intuitif, membolehkan konfigurasi mesin yang lancar dan kawalan fungsi elektronik yang tepat.

Sistem Pemantauan Bersepadu:

- Laserstop Bersepadu:Sistem pemantauan masa nyata lanjutan.

- Pilihan: Sistem Kamera:Menyediakan maklum balas visual masa nyata untuk ketepatan.

Sistem Pembuangan Benang:

Setiap kedudukan rasuk meledingkan mempunyaipemacu pelepasan benang dikawal secara elektronikuntuk peraturan ketegangan yang tepat.

Mekanisme Pengambilan Fabrik:

Dilengkapi dengan sebuahsistem pengambilan fabrik yang dikawal secara elektronikdigerakkan oleh motor bergear berketepatan tinggi.

Peranti Batching:

Sistem batching dengan lilitan permukaan.

Sistem Pemacu Corak:

- Standard:N-drive dengan tiga cakera corak dan gear tukar tempias bersepadu.

- Pilihan:Pemacu EL dengan motor dikawal secara elektronik, membenarkan bar panduan bergoyang sehingga 50mm (sambungan pilihan kepada 80mm).

Spesifikasi Elektrik:

- Sistem Pemacu:Pemacu terkawal kelajuan dengan jumlah beban tersambung sebanyak 25 kVA.

- Voltan:380V ± 10%, bekalan kuasa tiga fasa.

- Kord Kuasa Utama:Kabel empat teras tiga fasa minimum 4mm², wayar pembumian tidak kurang daripada 6mm².

Sistem Bekalan Minyak:

Majupenukar haba minyak/airmemastikan prestasi optimum.

Persekitaran Operasi:

- Suhu:25°C ± 6°C

- Kelembapan:65% ± 10%

- Tekanan Lantai:2000-4000 kg/m²

Kain mengait crinkle warp ialah pilihan yang sangat popular di kalangan fesyen pantas utama dan jenama mewah seperti Uniqlo, Zara dan HM. Mesin mengait meledingkan kami, khususnya Mesin Sisipan Weft, digunakan untuk menghasilkan fabrik bertekstur yang bergaya ini, memenuhi piawaian reka bentuk tinggi industri.

Fabrik langsir ini menggabungkan benang kasar bersepadu Lurex dengan tanah separa kusam, menghasilkan rupa metalik yang menarik. Ia kekal ringan secara visual kerana strukturnya yang telus namun stabil. Ketahanannya dalam kedua-dua panjang dan lebar menjadikannya sesuai untuk aplikasi sulaman juga.

Perlindungan Kalis AirSetiap mesin dimeterai dengan teliti dengan pembungkusan selamat laut, memberikan pertahanan yang teguh terhadap kelembapan dan kerosakan air sepanjang transit. | Kes Kayu Standard Eksport AntarabangsaSarung kayu komposit berkekuatan tinggi kami mematuhi sepenuhnya peraturan eksport global, memastikan perlindungan dan kestabilan optimum semasa pengangkutan. | Logistik Cekap & Boleh DipercayaiDaripada pengendalian berhati-hati di kemudahan kami hingga pakar memuat kontena di pelabuhan, setiap langkah proses penghantaran diuruskan dengan tepat untuk menjamin penghantaran yang selamat dan tepat pada masanya. |

HUBUNGI KAMI

HUBUNGI KAMI