GS-HKS 5-M-EL: Unleashing Boundless Possibilities in Shoe Fabric and Technical Textiles

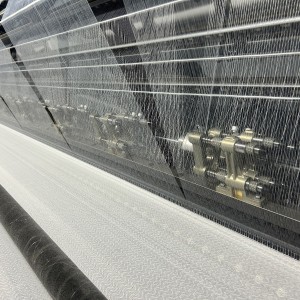

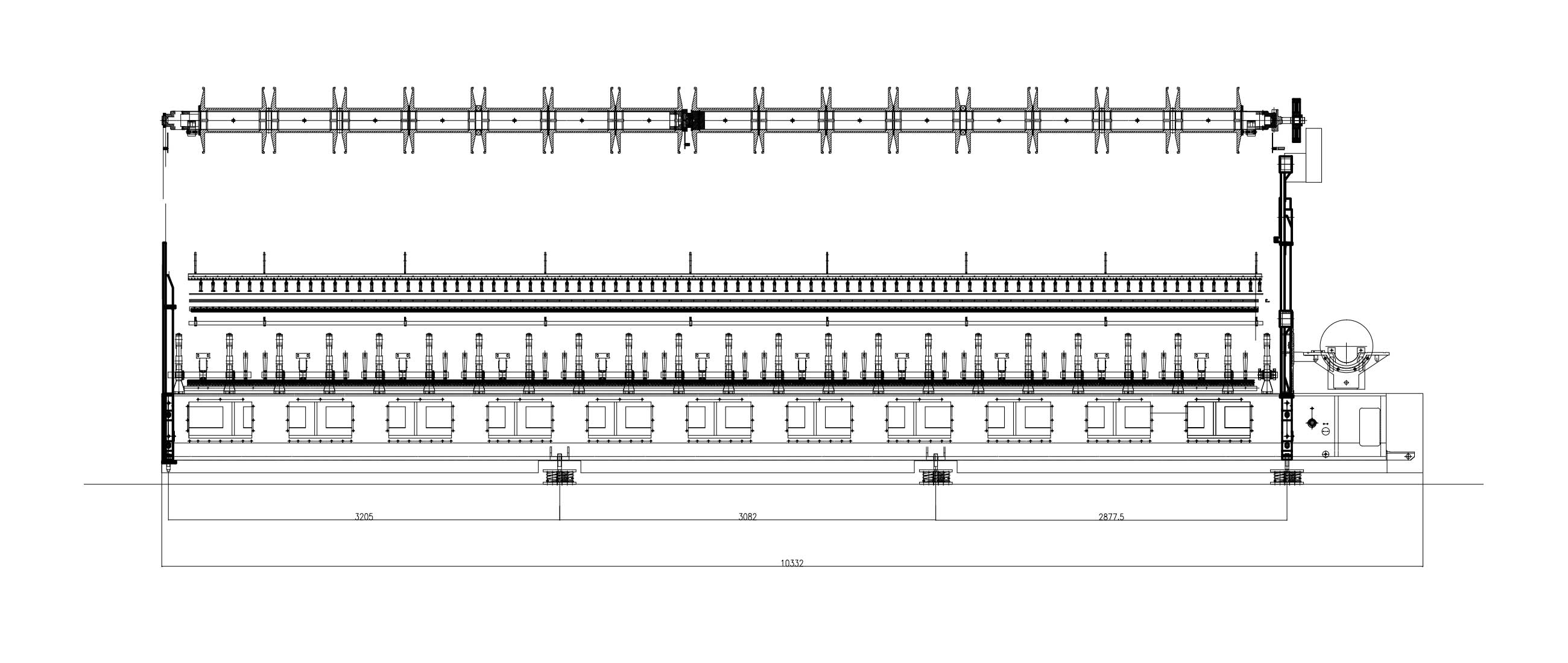

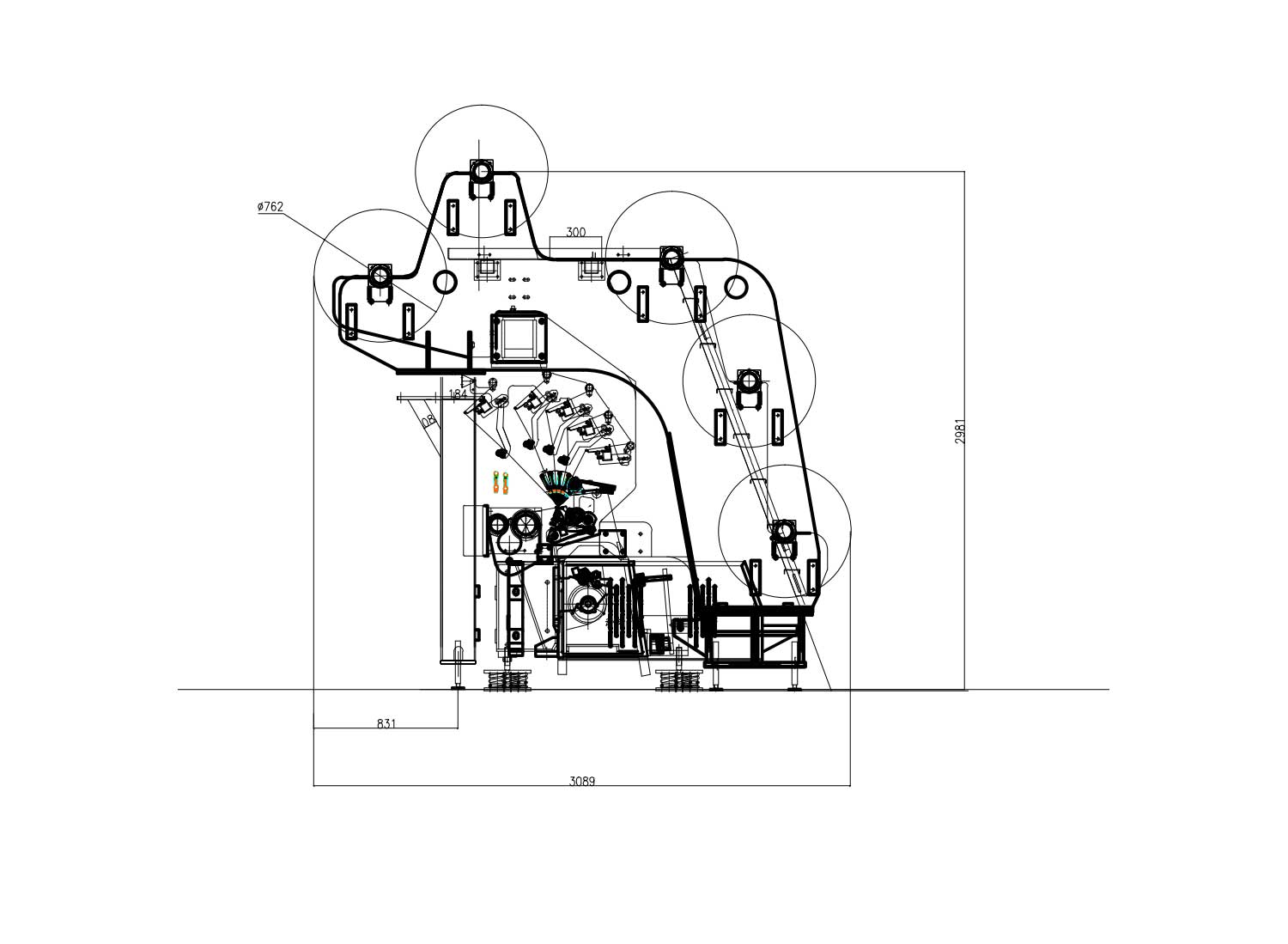

The GS-HKS 5-M-EL tricot machine from GrandStar Warp Knitting is an innovative solution designed to push the boundaries of textile production. By integrating the advanced EL (Electronic Guide Bar Control) system, this model offers an unparalleled ability to create an extensive range of patterns, making it the ideal choice for producing new shoe fabric patterns, complex Crinkle Fabrics, and other high-value textiles.

Revolutionizing Shoe Fabric Production

This machine stands out with its remarkable capabilities in shoe fabric manufacturing. A specialized coarse machine gauge, developed at GrandStar, enables the production of a multifaceted collection tailored specifically for this sector. The GS-HKS 5-M-EL has already impressed industry professionals with its ability to manufacture durable, stylish, and high-performance shoe fabrics.

Exceptional Fabric Properties for High-Performance Footwear

The fabrics produced with this machine are ideal for sports and leisure shoes, offering a unique blend of toughness, abrasion resistance, and striking visual appeal. A distinctive feature is the two-tone contrasting color effect, achieved through carefully selected polyester yarns:

- Ground Guide Bars (GB 1, GB 2, and GB 3): Textured, spin-dyed black polyester yarn enhances depth and pattern definition.

- GB 4 and GB 5: A smooth, semi-matt raw-white polyester, arranged in a 1-in/1-out threading, creates a visually dynamic pattern with varied-sized openings.

- Spin-dyed yarn: Produces high-contrast motifs that protrude clearly from the ground pattern.

Additionally, a fully threaded pillar stitch in GB 1 ensures enhanced fabric stability, while strategically placed underlaps across other guide bars provide increased abrasion resistance, crucial for high-wear applications.

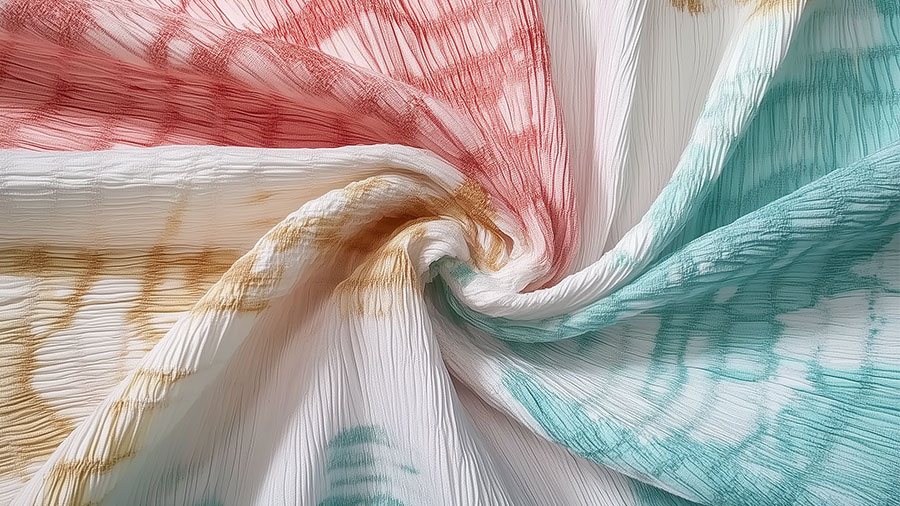

Unparalleled Versatility for Complex Crinkle Fabrics and Technical Textiles

Beyond shoe fabrics, the GS-HKS 5-M-EL is engineered to handle highly intricate Crinkle Fabrics, apparel textiles, and semi-technical fabrics. When configured in an E 28 gauge, this machine elevates fabric innovation to new heights.

The addition of a fifth guide bar—compared to traditional four-bar tricot machines—unlocks expanded design potential and pattern versatility. The Electronic Guide Bar Control (EL system), combined with five guide bars, ensures maximum flexibility, enabling manufacturers to create a broader range of designs with precision and efficiency.

A Future-Ready Tricot Machine for Innovative Textiles

The GS-HKS 5-M-EL sets new standards in warp knitting, offering unmatched flexibility, enhanced design capabilities, and superior fabric durability. Whether for high-performance shoe fabrics, intricate fashion textiles, or technical materials, this machine empowers manufacturers to achieve next-level innovation and excellence.

With GrandStar’s cutting-edge technology, the GS-HKS 5-M-EL paves the way for a new era of textile manufacturing, where creativity meets efficiency.

CONTACT US

CONTACT US