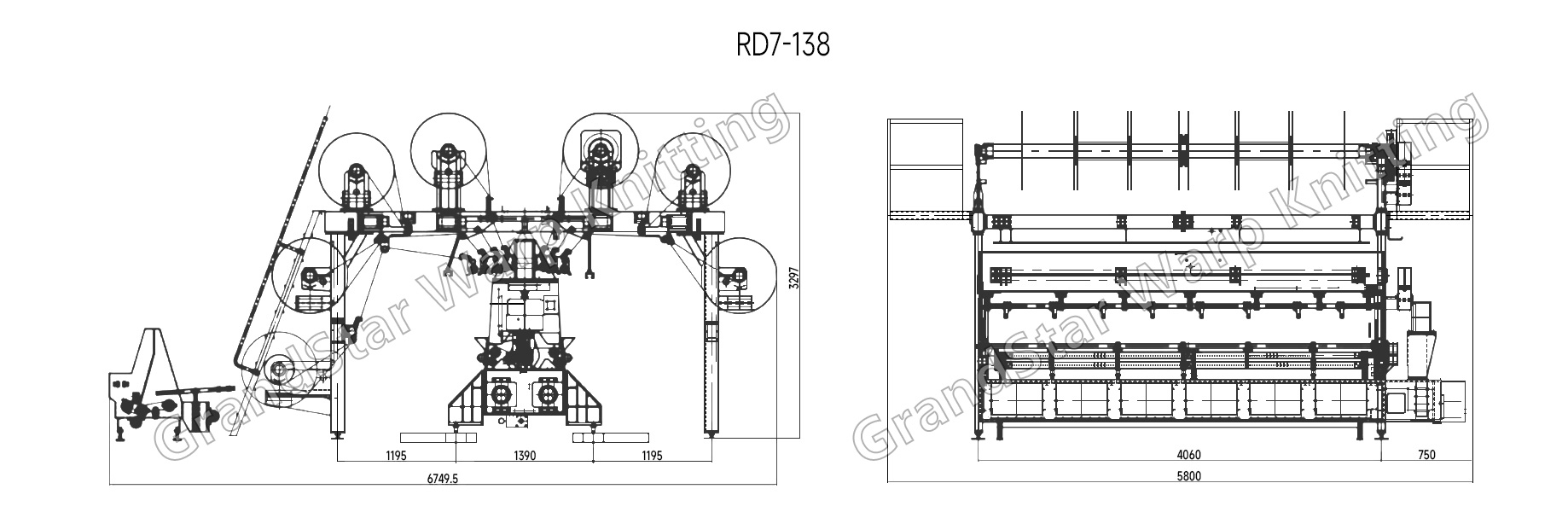

GS-RD7 2-12 (EL) Double Raschel Warp Knitting Machine

Working width / Gauge

- 3505 mm = 138″

- 5334 mm = 210″

- 7112 mm = 280″

- E18, E22, E24

Knock-over comb bar distance:

2–12 mm, continuously adjust able. Central trick plate distance readjustment

Bars / knitting elements

- Two needle bars with latch needle units, two knock-over comb bars and two moveable stitch comb bars, seven ground bars, GB4 and GB5 stitch forming on both needle bars

- Option: individual needle bars

- Option: GB3, GB4 and GB5 stitch forming on both needle bars

Warp beam support:

7 × 812 mm = 32″ (free-standing)

GrandStar®(GrandStar COMMAND SYSTEM)

Operator interface to configure, control and adjust the electronic functionality of the machine

Yarn Iet-off device

For each completely mounted warp beam position: one electronically controlled yarn Iet-off drive

Fabric take-up

Electronically regulated fabric take-up, driven by geared motor, consisting of four rollers.

Batching device

Separate rolling device

Pattern drive

- EN-drive with seven electronic guide bar drives.

- shog distance: ground 18 mm, pile 25 mm

- Optional for Electronic guide bar drive EL, all guide bars shog up to 150 mm

Electrical equipment

- Speed-regulated drive, total connected load of the machine: 7.5 KW

- Voltage: 380V±10% three-phase power supply, main power cord requirements: not less than 4m㎡ three-phase four-core power cord, ground wire not less than 6m㎡

Oil supply

Heating and cooling by means of circulating air heat exchanger, filter with dirt-monitoring system

Equipment working conditions

- Temperature 25℃±3℃, humidity 65%±10%

- Floor pressure: 2000-4000KG/㎡

CONTACT US

CONTACT US