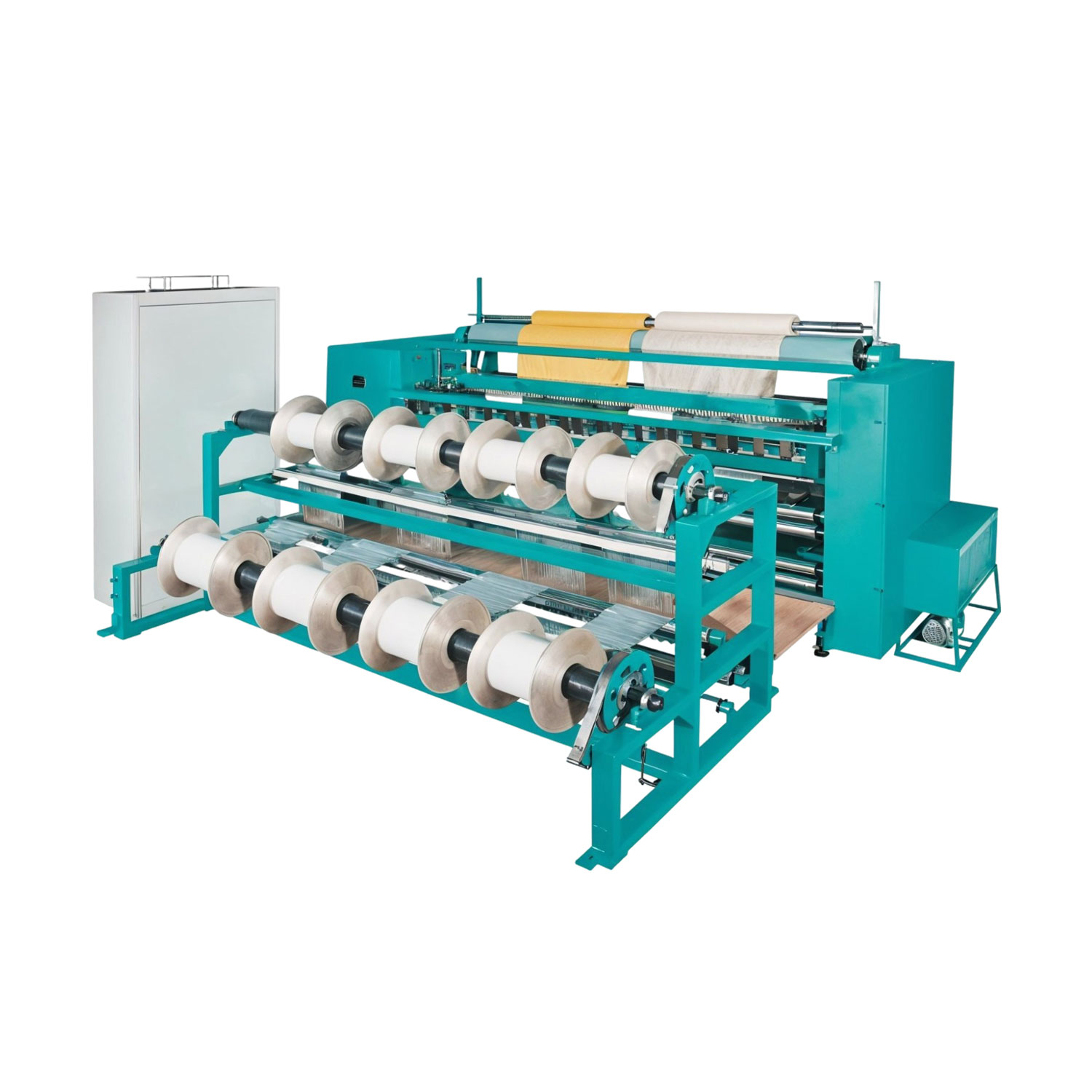

Meaisín Nascála Stitch Malimo/Maliwatt

Meaisín Cniotála Warp Stitch Bonding

Réitigh Nuálacha le haghaidh Teicstílí Teicniúla

AnMeaisín Cniotála Warp Stitch Bondingréiteach ceannródaíoch atá deartha le haghaidh táirgeadhteicstílí teicniúla, le fócas ar leith artáirgí gloine agus neamhfhiteÚsáidtear go forleathan é i dtionscail a bhfuil gá leoábhair chomhchodacha athneartaithe, fabraicí neamhfhite marthanacha, agus teicstílí ardfheidhmíochta.

Feidhmchláir Ilúsáideacha Trasna Tionscail

Ármeaisín nasctha stitchatá deartha chun freastal ar riachtanais éagsúla feidhmchlár, lena n-áirítear:

- Idirlíneáil bróg– Marthanacht agus compord a fheabhsú.

- Málaí siopadóireachta– Roghanna fabraice neart agus atá neamhdhíobhálach don chomhshaol a sholáthar.

- Éadaí mias agus tuáillí indiúscartha– Ard-ionsúiteacht agus éifeachtúlacht costais a chinntiú.

- Teicstílí snáithíní gloine ilchodacha treisithe– Neart den scoth a thairiscint d’fheidhmchláir thionsclaíocha.

Innealtóireacht Beachtas le haghaidh Éifeachtúlachta Uasta

Deartha dooibriú ardluais agus éifeachtach, comhtháthaíonn ár meaisíní nasctha greamaithecórais scaoilte leictreonacha chun cinn agus dioscaí patrúna chinntiúbeathú snáth cobhsaí, beacht agus cáilíocht fabraice chomhsheasmhach.

Príomhghnéithe:

- Cumraíochtaí meaisín solúbtha:Ar fáil iSocruithe 2-bharra go 4-bharrachun freastal ar riachtanais éagsúla táirgthe teicstíle.

- Cumas leithead leathan:Ag síneadh ó130 orlach go 245 orlachle haghaidh feidhmeanna fabraice éagsúla.

- Comhéadan scáileáin tadhaill atá furasta le húsáid:Ceadaíonnmonatóireacht fíor-ama, taifeadadh sonraí táirgeachta, agus coigeartuithe paraiméadair fabraice.

- Nascacht chliste:Cumasaíonnaistriú sonraí iargúlta tríd an idirlíon, bainistíocht táirgeachta a bharrfheabhsú agus éifeachtúlacht a fheabhsú.

Cén fáth a roghnófá ár meaisín nascála greamaitheach?

Tugann ár ndearadh meaisín tús áiteéascaíocht oibríochta, ardéifeachtúlacht, agus feidhmíocht teicstíle den scothCibé acu le haghaidhfabraicí teicniúla treisithe nó táirgí neamhfhite nuálacha, ármeaisín cniotála dlúth nasctha stitchseachadanniontaofacht agus táirgiúlacht gan sárúchun freastal ar éilimh mhéadaitheacha an tionscail teicstíle.

Déan iniúchadh ar thodhchaí tháirgeadh teicstílí teicniúla lenár dteicneolaíocht nasctha fuála chun cinn.

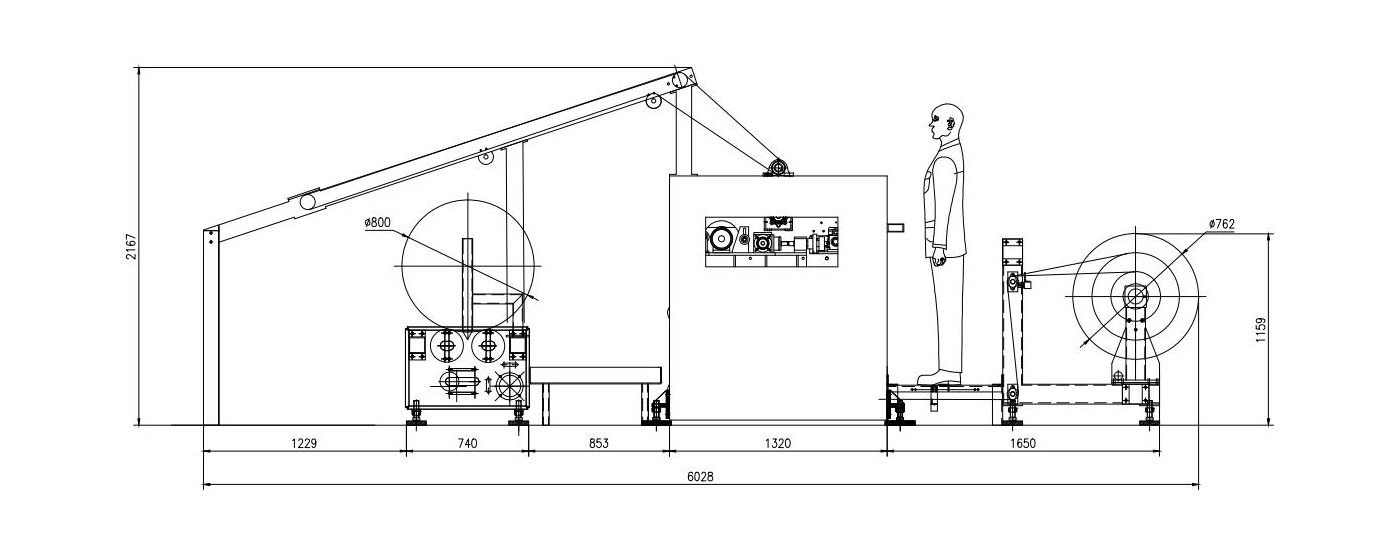

Roghanna Leithead Oibre

- 2000mm, 2800mm, 3600mm, 4400mm, 4800mm, 5400mm, 6000mm

Roghanna Tomhsaire

- F7, F12, F14, F16, F18, F20, F22

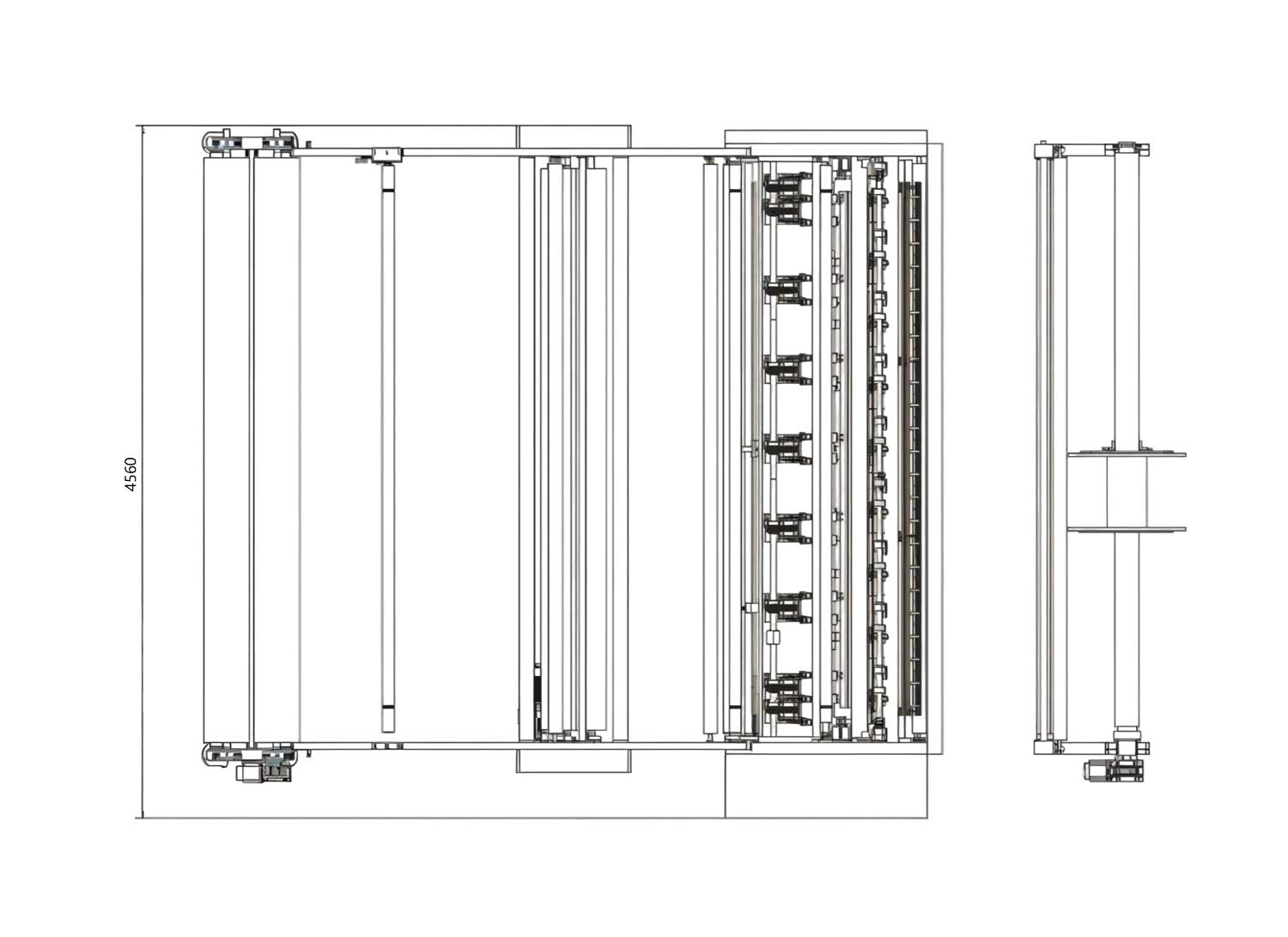

Eilimintí Cniotála

- Barra snáthaide cumaiscle haghaidh foirmiú lúb beacht

- Barra sreinge dúntale haghaidh foirmiú fuála slán

- Barra doirteal cnagthachun cobhsaíocht fabraice a fheabhsú

- Barra tacaíochtale haghaidh athneartaithe struchtúraigh

- Barra frithchoinneálachun cruinneas cniotála feabhsaithe a fheabhsú

- Barraí treorach talúnInchumraithe mar1 nó 2 bharrale haghaidh solúbthachta patrún

Córas Tiomána Patrún – N

- Sásra tiomána Nle teicneolaíocht diosca patrún

- Tiomáint fearas athraithe teochta comhtháitele haghaidh coigeartú patrún optamaithe

- Diosca patrún aonairag cinntiú patrúnú beacht agus solúbtha

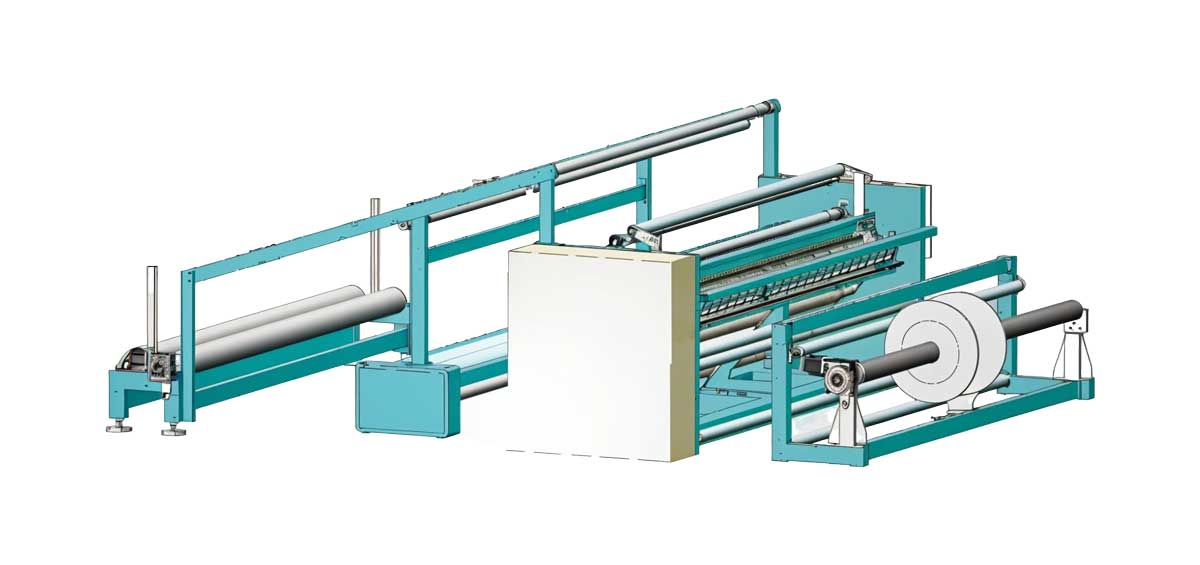

Córas Tacaíochta Bhíoma Warp

- Inchumraithe1 nó 2 shuíomh bhíoma dlúthle haghaidh feidhmchlár rannóige

- Uasmhéidtrastomhas flange: 30 orlach, ag cinntiú éifeachtúlacht fheabhsaithe soláthair snáth

Córas Scaoilte Snáth

- Tiomáint scaoilte snáth rialaithe go leictreonachle haghaidh rialáil teannas comhsheasmhach

- Mótar giaráilte le tiontaire minicíochta, ag cinntiú rialú beacht agus oibriú réidh

Gluaiseacht Stop Snáth (Roghnach)

- Córas rialaithe go leictreonachchun feabhas a chur ar bhrath briste snáth agus ar éifeachtúlacht táirgthe

Córas Tógála Fabraice

- Córas tógála fabraice atá rialaithe go leictreonachle haghaidh seachadadh comhsheasmhach fabraice

- Mótar giaráilte le tiontaire minicíochtaag cinntiú cruinneas agus iontaofacht ard

Gléas Baisceála (Neamhspleách)

- Tiomáint frithchuimilte le sorcóir brúle haghaidh foirceannadh fabraice réidh

- Uasmhéidtrastomhas bhaisc: 914mm (36 orlach)

- Mótar giaráilte le tiontaire minicíochta comhtháitele haghaidh rialú níos fearr

Córas Rialaithe Gluaiseachta Ardleibhéil

- Rialú MeaisínCóras ríomhairithe comhtháite le haghaidh comhordú beacht an phríomhthiomáint, an bheathú snáth, agus an tógáil fabraice

- Comhéadan Oibreora: Intuigthepainéal tadhaillmonatóireacht agus rialú táirgeachta fíor-ama a sholáthar

Córas Leictreach

- Tiomáint rialaithe luaisle feidhmeanna sábháilteachta comhtháite i gcás cliseadh cumhachta

- Rialú aonluaisdo gach príomhfheidhm meaisín trítiontaire minicíochta

Príomhchumhacht Mótair

- Leithead oibre 2000mm–4400mm: 13 cileavata

- Leithead oibre 4400mm–6000mm: 18 cileavata

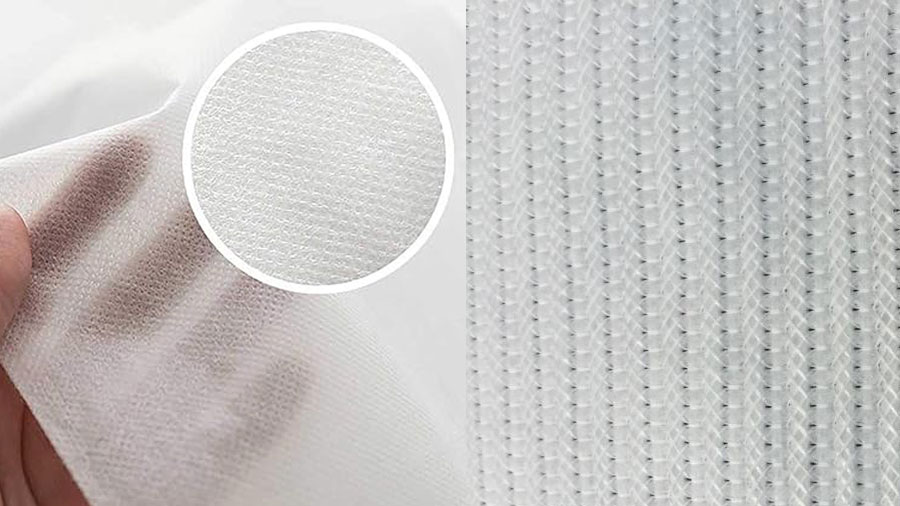

Déantar fabraic Stitchbond as buidéil phlaisteacha athchúrsáilte ardchaighdeáin, a phróiseáiltear ina snáithín ceimiceach. Ag baint úsáide as próiseas neamhfhite, comhcheanglaíonn sé poileistear athchúrsáilte le filiméid poileistear préimhe le haghaidh marthanachta agus feidhmíochta.

Tá ár n-éadach líneála spunbond uiscedhíonach ardchaighdeáin agus ár n-éadach glantacháin neamhfhite deartha le haghaidh marthanachta agus éifeachtúlachta. Le meáchan bonn de 33gsm go 100gsm, tá na fabraicí seo déanta as 100% snáithín nádúrtha, meascán snáithín nádúrtha-poileistear, nó 100% poileistear. Cuireann siad neart láidir, in-niteacht, agus ionsú uisce den scoth ar fáil, rud a fhágann go bhfuil siad oiriúnach le haghaidh glantacháin agus feidhmeanna cistine.

Cosaint UiscedhíonachTá gach meaisín séalaithe go cúramach le pacáistiú atá sábháilte don fharraige, rud a sholáthraíonn cosaint láidir i gcoinne damáiste taise agus uisce le linn an iompair. | Cásanna Adhmaid Caighdeánacha Easpórtála IdirnáisiúntaComhlíonann ár gcásanna adhmaid ilchodacha ard-neart go hiomlán rialacháin onnmhairithe domhanda, rud a chinntíonn cosaint agus cobhsaíocht is fearr le linn iompair. | Loighistic Éifeachtach & IontaofaÓ láimhseáil chúramach inár saoráid go luchtú coimeádán saineolach ag an gcalafort, déantar gach céim den phróiseas loingseoireachta a bhainistiú go beacht chun seachadadh sábháilte agus tráthúil a ráthú. |

TÉIGH I dTEAGMHÁIL LINN

TÉIGH I dTEAGMHÁIL LINN