KSJ-3/1 (EL) ትሪኮት ማሽን ከጃክኳርድ ጋር

የጨርቃጨርቅ የመሬት ገጽታህን አሻሽል፡-

የ KSJ JACQUARD TRICOT ማሽንን በማስተዋወቅ ላይ

ከዚህ በፊት ታይቶ የማያውቅ የንድፍ ነፃነትን ያውጡ እና የጨርቅ አፈጻጸምዎን በሚቀጥለው የዋርፕ ሹራብ ቴክኖሎጂ ያሳድጉ።

ከመደበኛው ባሻገር፡ ከትሪኮት ገደቦች መላቀቅ

ለብዙ አሥርተ ዓመታት, Tricot warp ሹራብ ከቅልጥፍና እና ወጥ የሆነ የጨርቅ ምርት ጋር ተመሳሳይ ነው. ነገር ግን፣ ባህላዊ ትሪኮት ማሽኖች በተፈጥሯቸው የዲዛይን ወሰን ውስን ናቸው። ጠንካራ ጨርቆች, ቀላል ጭረቶች - እነዚህ ወሰኖች ነበሩ. ተፎካካሪዎች የፈጠራ እይታዎን እና የገበያ ልዩነትዎን የሚገድቡ ይህንን ሁኔታ የሚጠብቁ ማሽኖችን ያቀርባሉ። እነዚህን ገደቦች ለማለፍ እና ወደ አዲስ የጨርቅ ፈጠራ ዘመን ለመግባት ዝግጁ ነዎት?

የKSJ Jacquard Tricot በማስተዋወቅ ላይ፡ ትክክለኛነት ምናብን የሚያሟላበት

የ KSJ Jacquardትሪኮት ማሽንየዝግመተ ለውጥ ብቻ አይደለም - ሀየፓራዳይም ለውጥ. እጅግ በጣም ጥሩ የሆነ የጃክኳርድ ስርዓትን ፈጠርን እና ከታዋቂው የትሪኮት መድረክ ጋር ያለምንም እንከን አዋህደነዋል፣ ይህም ከዚህ ቀደም በጦርነት ሹራብ የማይቻል ነው የተባለውን ነገር እንዲያሳኩ የሚያስችልዎት ነው። የጨርቅ ንድፍ እንደገና ለመወሰን እና ለማግኘት ያዘጋጁየማይታለፍ የውድድር ጥቅም.

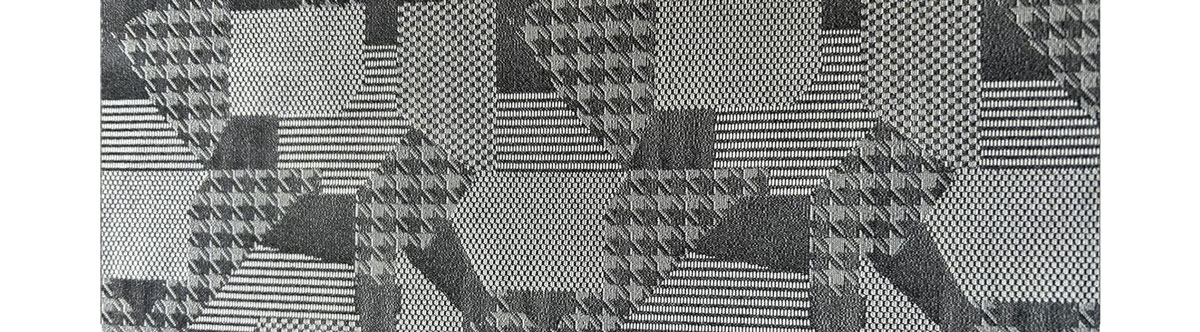

- ያልተለቀቀ ንድፍ ሁለገብነት;ከተጣራ ጨርቆች እገዳዎች ይላቀቁ። የእኛ የላቀ የJacquard ስርዓት ውስብስብ ነገሮችን ለመፍጠር የሚያስችል የግለሰብ መርፌ ቁጥጥር ይሰጥዎታልዳንቴል የሚመስሉ አወቃቀሮች፣ የተራቀቁ የጂኦሜትሪክ ንድፎች እና አስደናቂ ረቂቅ ንድፎች. ተፎካካሪዎች የተገደበ የስርዓተ-ጥለት አቅም ይሰጣሉ - KSJ ያቀርባልገደብ የለሽ የመፍጠር አቅም.

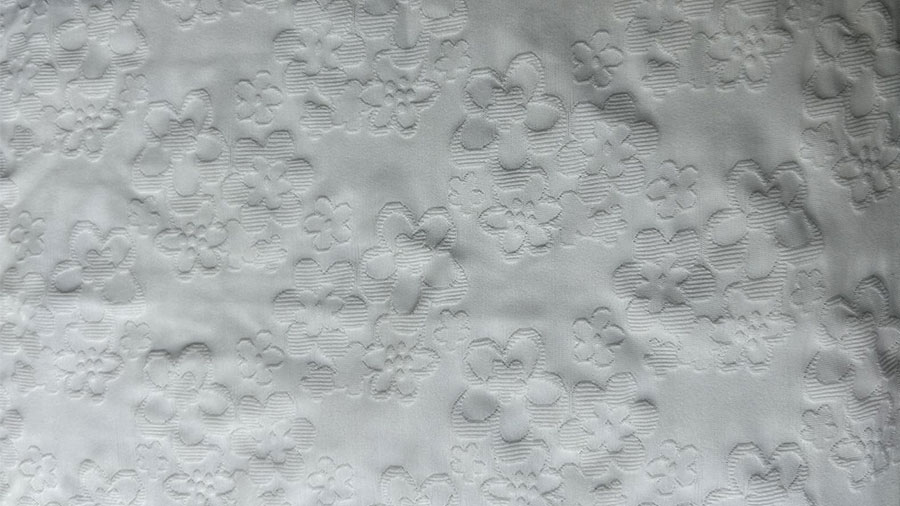

- ከፍ ያለ የገጽታ ሸካራነት እና ልኬት፡ጠፍጣፋ ፣ ወጥ ከሆኑ ወለሎች በላይ ይሂዱ። የKSJ Jacquard ጨርቁን እንዲቀርጹ ኃይል ይሰጥዎታል3D ሸካራማነቶች፣ የተነሱ ቅጦች እና ክፍት የስራ ውጤቶች. የዕደ-ጥበብ ጨርቆች ወደር የለሽ የመዳሰሻ ማራኪነት እና የእይታ ጥልቀት ፣ ከጠፍጣፋው በላይ ፣ ባህላዊ ማሽኖች መሰረታዊ አቅርቦቶች።

- ተግባራዊ የጨርቅ ፈጠራ፡ጋር መሐንዲስ ጨርቆችየዞን ተግባራዊነትበትክክል ከአፈጻጸም ፍላጎቶች ጋር የተጣጣመ። በአንድ የጨርቅ መዋቅር ውስጥ የተቀናጀ የሜሽ አየር ማናፈሻ፣ የተጠናከረ የድጋፍ ዞኖች ወይም የተለያየ የመለጠጥ ችሎታ ይፍጠሩ። ተፎካካሪ ማሽኖች አንድ አይነት ጨርቅ ያመርታሉ - KSJ ያቀርባልየአፈፃፀም ችሎታዎች ።

- የተሻሻለ ቅልጥፍና እና ትክክለኛነት፡የንድፍ ድንበሮችን ስንገፋ፣ ለውጤታማነት ያለንን ቁርጠኝነት እንጠብቃለን። የ KSJ Jacquard ትሪኮት አብሮ ይሰራልተመጣጣኝ ያልሆነ ትክክለኛነት እና ከፍተኛ ፍጥነት ያለው አስተማማኝነት፣ የመቀነስ ጊዜን በመቀነስ እና ውጤቱን ከፍ ማድረግ። ለንድፍ ምርታማነትን አታበላሹ - በKSJ ፣ ሁለቱንም አሳክተዋል።

- የገበያ መዳረሻዎን ያስፋፉ፡-የተራቀቁ እና የተለዩ ጨርቆችን የሚጠይቁ ከፍተኛ ዋጋ ያላቸውን ገበያዎች ያቅዱ። ከከፍተኛ ፋሽን የውጪ ልብሶች እና የውስጥ ልብሶች to አዳዲስ ቴክኒካል ጨርቃ ጨርቅ እና የቅንጦት የቤት ዕቃዎች፣ KSJ Jacquard ቀደም ሲል በመደበኛ ትሪኮት ሊገኙ ላልቻሉ ፕሪሚየም መተግበሪያዎች በሮችን ይከፍታል። ተፎካካሪዎች ገበያዎን ይገድባሉ - KSJ የእርስዎን ግንዛቤ ያሰፋል።

- የላቀ የጨርቅ ጥራት እና ወጥነት፡በKSJ ምህንድስና በዓለት-ጠንካራ መሠረት ላይ የተገነባው ይህ ማሽን በልዩ ሁኔታ ጨርቆችን ያቀርባልልኬት መረጋጋት፣ የሩጫ መቋቋም እና ወጥነት ያለው ጥራት, ለፍላጎት አፕሊኬሽኖች አስፈላጊ. ንድፍ ብቻ አናቀርብም - ዋስትና እንሰጣለንአፈጻጸም እና አስተማማኝነት.

የKSJ ጥቅማጥቅሞች፡ ወደ ዲዛይን እና የአፈጻጸም ብቃት ጠለቅ ይበሉ

የውበት ፈጠራን መቆጣጠር

ከባህላዊ ዳንቴል ውበት ጋር የሚወዳደሩ ጨርቆችን አስብ፣ ነገር ግን የዋርፕ ሹራብ ተፈጥሯዊ የአፈፃፀም ጥቅሞችን አሏቸው። የ KSJ Jacquard ትክክለኛ መርፌ ምርጫ ለመፍጠር ያስችላልአስደናቂ ክፍት የስራ ቅጦች, ለስላሳ የአበባ ዘይቤዎች እና ውስብስብ የጂኦሜትሪክ ንድፎች. የእርስዎን የፋሽን ስብስቦች እና የቤት ውስጥ ጨርቃ ጨርቅ ትኩረትን በሚስቡ እና ፕሪሚየም ዋጋን በሚያዝዙ ጨርቆች ያሳድጉ።

ተግባራዊ ሁለገብነት መክፈት

ከውበት ባሻገር፣ KSJ Jacquard ለተግባራዊ ፈጠራ ሃይል ነው። ጋር መሐንዲስ ጨርቆችየተቀናጁ የአፈፃፀም ዞኖች- ለስፖርት ልብስ የሚተነፍሰው ጥልፍልፍ፣ ለኢንዱስትሪ አፕሊኬሽኖች የተጠናከረ ክፍሎች ወይም ለተመቻቸ ልብስ የሚመጥን የተለያዩ የመለጠጥ ቦታዎች። የተጣመሩ ጨርቆች ምን ሊያገኙ እንደሚችሉ ድንበሮችን በመግፋት ብልጥ ጨርቃ ጨርቅን በተሰራ ተግባር ይፍጠሩ።

የመዋቅር ጌትነት እና የ3-ል ተፅእኖዎች

በKSJ Jacquard የመፍጠር ችሎታ የጨርቆችዎን የመዳሰስ ልምድ ይለውጡ3D ሸካራማነቶች ይጠራ. ለዲዛይኖችዎ አዲስ ልኬት የሚጨምሩ የጎድን አጥንቶችን፣ ባለገመድ ተጽእኖዎችን እና የተዋቀሩ ንጣፎችን ይፍጠሩ። ከፋሽን ልብሶች እስከ ጨርቃ ጨርቅ ድረስ በእይታ አስደናቂ ብቻ ሳይሆን ልዩ የሆነ የስሜት ህዋሳትን የሚያቀርቡ ጨርቆችን ይፍጠሩ።

የላቀ፣ አዲስ ፈጠራ፣ ከንድፍ ውጪ፡ የKSJ ልዩነት

በተለመዱ አቅርቦቶች በተሞላ ገበያ የKSJ Jacquard Tricot ማሽን የእርስዎ ስትራቴጂያዊ ጥቅም ነው። ተፎካካሪዎች ውስንነትን የሚያራምዱ ማሽኖችን ሲያቀርቡ፣ KSJ እንዲያደርጉ ኃይል ይሰጥዎታልወደ ፊት መዝለል. የተለያዩ ብቻ ሳይሆን በንድፍ ውስብስብነት፣ ተግባራዊነት እና በገበያ ማራኪነት የላቁ ጨርቆችን ይፍጠሩ። በKSJ ኢንቨስት ያድርጉ እና ኢንቨስት ያድርጉየወደፊት-ማስረጃ ፈጠራ.

የወደፊቱን የዋርፕ ሹራብ ተለማመዱ። ዛሬ።

የጨርቅ ምርትዎን ለመለወጥ እና ከዚህ በፊት ታይቶ የማያውቅ የንድፍ እድሎችን ለመክፈት ዝግጁ ነዎት? ስለ KSJ Jacquard Tricot ማሽን የበለጠ ለማወቅ፣ ዝርዝር ብሮሹር ለመጠየቅ ወይም ግላዊ የሆነ ምክክር ለማቀድ የባለሙያ ቡድናችንን ያግኙ። የጨርቃጨርቅ ፈጠራን እንደገና እንዲገልጹ እና ወደር የለሽ የገበያ ስኬት እንዲያገኙ እንረዳዎታለን።

GrandStar® Warp ሹራብ ማሽን መግለጫዎች

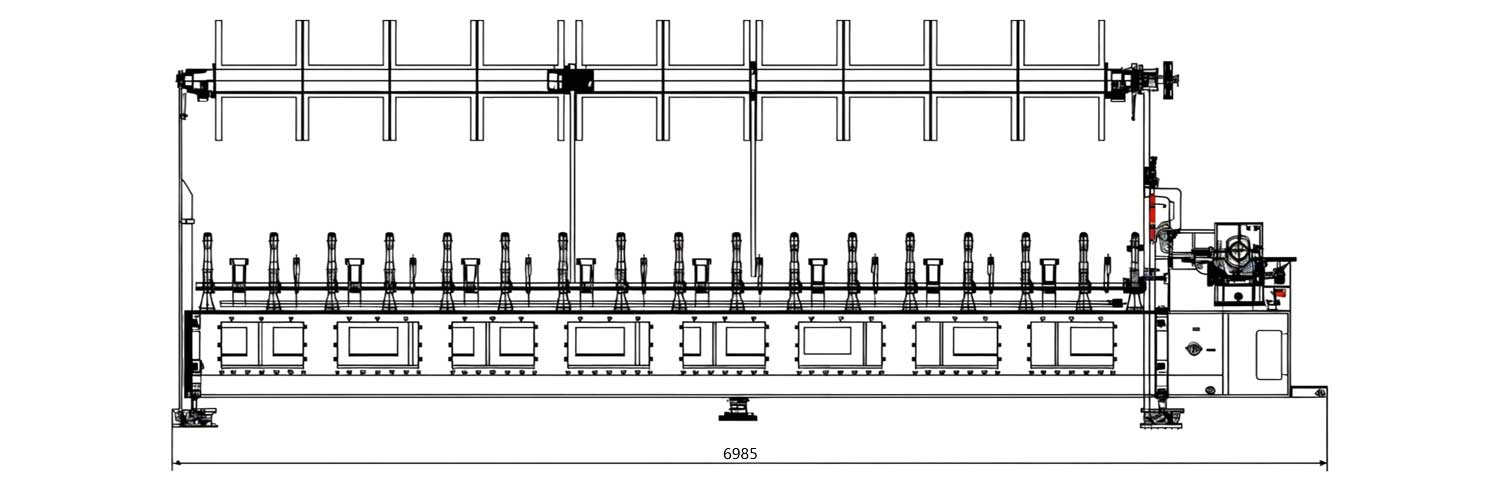

የስራ ስፋት አማራጮች፡-

- 3505 ሚሜ (138 ኢንች)

- 6045 ሚሜ (238 ኢንች)

የመለኪያ አማራጮች፡

- E28 እና E32

የሹራብ ክፍሎች፡

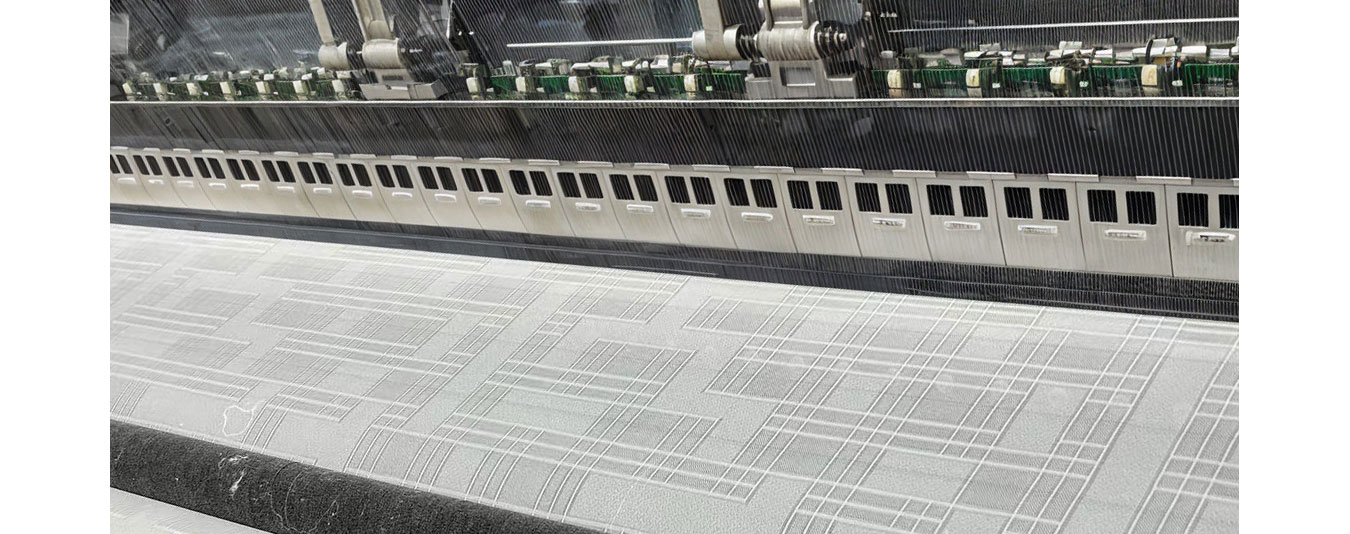

- የመርፌ አሞሌ፡የተዋሃዱ መርፌዎችን በመጠቀም 1 ነጠላ መርፌ አሞሌ።

- የተንሸራታች አሞሌ፡1 ተንሸራታች ባር ከጠፍጣፋ ተንሸራታች ክፍሎች (1/2 ኢንች)።

- የመታጠቢያ ገንዳ;የውሁድ ማጠቢያ ክፍሎችን የሚያሳይ 1 ማጠቢያ ባር።

- መመሪያ አሞሌዎች:2 መመሪያ አሞሌዎች ከትክክለኛ-ምህንድስና መመሪያ ክፍሎች ጋር።

- ጃክካርድ ባር፡2 የፓይዞ መመሪያ አሞሌዎች (1 ቡድን) ከገመድ አልባ-ፓይዞ ጃክኳርድ ጋር (የተከፋፈለ አፈፃፀም)።

- ቁሳቁስ፡ለላቀ ጥንካሬ እና ንዝረትን ለመቀነስ የካርቦን-ፋይበር-የተጠናከሩ ድብልቅ አሞሌዎች።

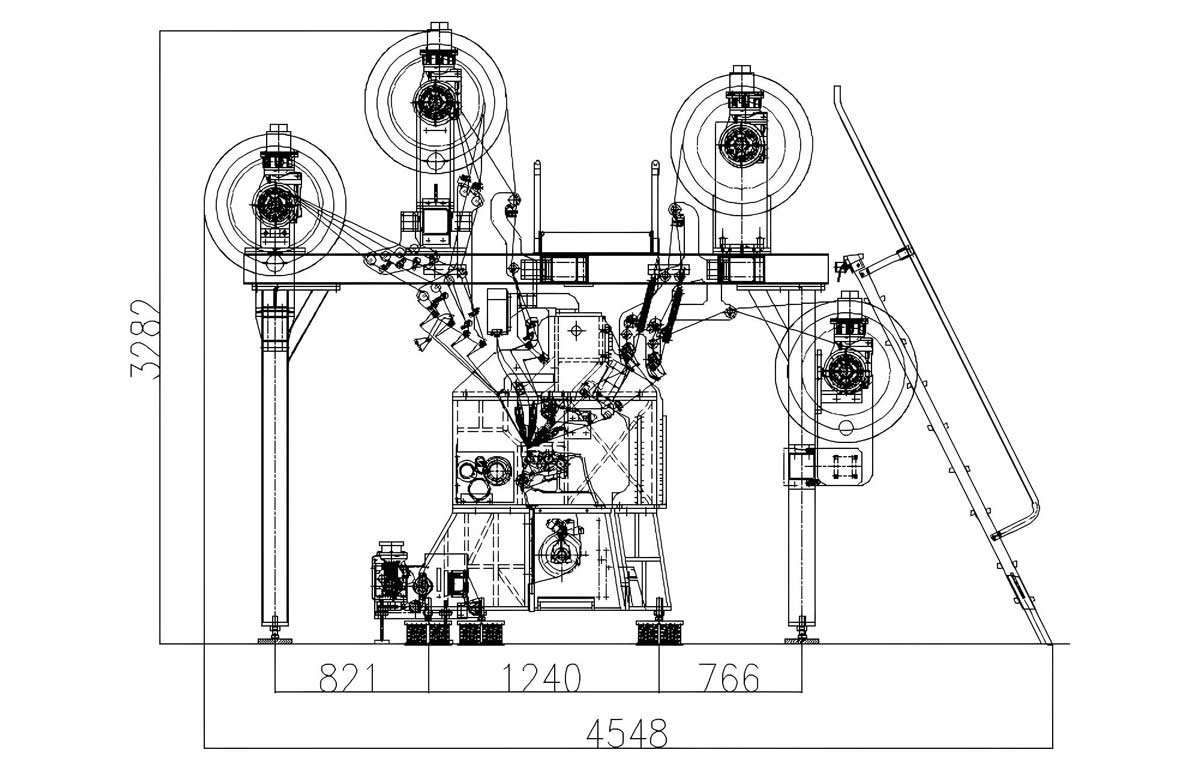

Warp Beam ድጋፍ ውቅረት፡-

- መደበኛ፡4 × 812 ሚሜ (32 ኢንች) (ነጻ የሚቆም)

- አማራጭ፡

- 4 × 1016 ሚሜ (40 ኢንች) (ነጻ የሚቆም)

- 1 × 1016 ሚሜ (40″) + 3 × 812 ሚሜ (32″) (ነጻ የሚቆም)

GrandStar® መቆጣጠሪያ ስርዓት፡-

የGrandStar COMMAND ስርዓትእንከን የለሽ የማሽን ውቅር እና ትክክለኛ የኤሌክትሮኒክስ ተግባር ቁጥጥርን በመፍቀድ ሊታወቅ የሚችል ኦፕሬተር በይነገጽ ይሰጣል።

የተዋሃዱ የክትትል ስርዓቶች;

- የተዋሃደ ሌዘርስቶፕ፡የላቀ ቅጽበታዊ ክትትል ሥርዓት.

ክር የማስለቀቂያ ስርዓት;

እያንዳንዱ የዋርፕ ጨረር አቀማመጥ የበኤሌክትሮኒካዊ ቁጥጥር የሚደረግለት ፈትል መልቀቅለትክክለኛው የጭንቀት መቆጣጠሪያ.

የጨርቃጨርቅ መጠቀሚያ ዘዴ;

የተገጠመለትበኤሌክትሮኒካዊ ቁጥጥር የሚደረግበት የጨርቅ ማስቀመጫ ስርዓትበከፍተኛ ትክክለኛነት በሚንቀሳቀስ ሞተር የሚነዳ።

የማጣቀሚያ መሳሪያ፡

A የተለየ ወለል-ቆመ ጨርቅ የሚጠቀለል መሳሪያለስላሳ የጨርቅ ብስባዛን ያረጋግጣል.

የስርዓተ ጥለት ድራይቭ ስርዓት፡

- ኤል-ድራይቭ በኤሌክትሮኒካዊ ቁጥጥር የሚደረግላቸው ሞተሮች፣ የመመሪያ አሞሌዎች እስከ 50ሚሜ (በአማራጭ እስከ 80 ሚሜ ማራዘሚያ) እንዲንሸራተቱ ያስችላቸዋል።

የኤሌክትሪክ መስፈርቶች

- የማሽከርከር ስርዓት፡የፍጥነት መቆጣጠሪያ ድራይቭ ከጠቅላላው የተገናኘ ጭነት 25 ኪ.ቮ.

- ቮልቴጅ፡380V ± 10%, ሶስት-ደረጃ የኃይል አቅርቦት.

- ዋና የኃይል ገመድ;ቢያንስ 4 ሚሜ ² ባለሶስት-ደረጃ ባለአራት ኮር ኬብል፣ የከርሰ ምድር ሽቦ ከ6 ሚሜ ² ያላነሰ።

የዘይት አቅርቦት ስርዓት;

የላቀዘይት / የውሃ ሙቀት መለዋወጫጥሩ አፈጻጸምን ያረጋግጣል.

የአሠራር አካባቢ;

- የሙቀት መጠን፡25 ° ሴ ± 6 ° ሴ

- እርጥበት;65% ± 10%

- የወለል ግፊት;2000-4000 ኪ.ግ/ሜ

የKSJ Jacquard ትክክለኛ የመርፌ መምረጫ እደ-ጥበብ አስደናቂ የክፍት ስራ ቅጦች፣ ስስ አበባዎች እና ውስብስብ ጂኦሜትሪ - ዳንቴል መሰል ውበትን ለፋሽን እና ለቤት ጨርቃጨርቅ ያመጣል።

በKSJ Jacquard የላቀ 3D ውጤቶች የጨርቅ ሸካራነትን ያሳድጉ። ወደ ንድፍዎ ጥልቀት እና ስፋት የሚያመጡ የጎድን የጎድን አጥንቶች፣ ባለገመድ ንድፎችን እና የተዋቀሩ ንጣፎችን ይፍጠሩ። ለፋሽን እና ለጨርቃ ጨርቅ ተስማሚ ናቸው, እነዚህ ጨርቆች ለእይታ እና ለመንካት ይማርካሉ.

የውሃ መከላከያ መከላከያእያንዳንዱ ማሽን ከባህር-አስተማማኝ ማሸጊያዎች ጋር በጥሩ ሁኔታ የታሸገ ሲሆን ይህም በእርጥበት እና በውሃ ላይ በሚደርሰው መጓጓዣ ውስጥ ጠንካራ መከላከያ ያቀርባል. | አለምአቀፍ ኤክስፖርት-መደበኛ የእንጨት መያዣዎችየእኛ ከፍተኛ ጥንካሬ የተቀናጀ የእንጨት መያዣዎች ከአለም አቀፍ የኤክስፖርት ደንቦች ጋር ሙሉ በሙሉ ያከብራሉ, በመጓጓዣ ጊዜ ጥሩ ጥበቃ እና መረጋጋትን ያረጋግጣሉ. | ውጤታማ እና አስተማማኝ ሎጅስቲክስበተቋማችን በጥንቃቄ ከመያዝ ጀምሮ እስከ ወደብ ላይ የባለሙያ ኮንቴይነሮችን መጫን፣ እያንዳንዱ የማጓጓዣ ሂደት ደህንነቱ የተጠበቀ እና ወቅታዊ ርክክብን ለማረጋገጥ በትክክለኛ መንገድ የሚተዳደር ነው። |

አግኙን።

አግኙን።